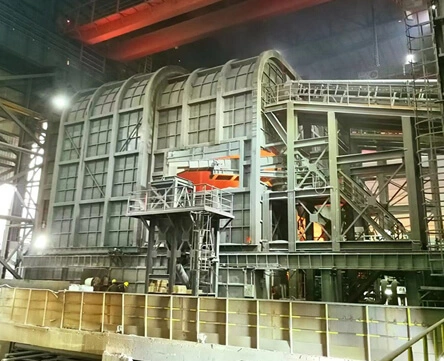

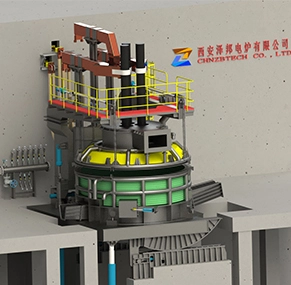

Meltshop auxiliary machines are vital components within the steel manufacturing process. These types of steel making furnaces, ranging from electric arc furnaces and ladle refining equipment to continuous casting machines, play a crucial role in refining raw materials and controlling steel properties. By meticulously managing factors such as composition and temperature, these devices contribute to the production of high-quality end products.

However, the meltshop environment is fraught with hazards, including extreme heat, swirling dust, molten metal, and open flames. Consequently, cooling water systems, dust collection units, and other safety measures are indispensable in minimizing risks and optimizing production processes.

With advancements in technology, innovative auxiliary machines like continuous casting systems and vacuum degassing units not only enhance steel quality but also promote sustainable practices by minimizing waste and energy consumption. As stewards of quality and safety, meltshop auxiliary machines remain pivotal in shaping the steel industry's future.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa