Comparison of AOD (Argon Oxygen Decarburization) and VOD (Vacuum Oxygen Decarburization) in the metal-making process, considering that your plant does not have a Ladle Refining Furnace (LRF) or power allocation for LRF:

AOD (Argon Oxygen Decarburization) Advantages:

1. Cost-Effective: AOD is generally more cost-effective compared to VOD, especially for large-scale production.

2. Efficiency: It is highly efficient in reducing carbon content in stainless steel and other high-alloy steels.

3. Flexibility: AOD can handle a wide range of alloy compositions and is particularly effective for producing stainless steel.

4. Lower Power Requirements: AOD does not require as much power as VOD, which is beneficial given your plant’s power constraints.

Disadvantages:

1. Limited Dephosphorization and Desulfurization: AOD is less effective in removing phosphorus and sulfur compared to VOD.

2. Higher Nitrogen Levels: The process can introduce higher levels of nitrogen into the steel, which may not be desirable for certain applications.

3. Less Control Over Impurities: AOD offers less control over the removal of certain impurities compared to VOD.

VOD (Vacuum Oxygen Decarburization) Advantages:

1. High Purity: VOD is highly effective in producing ultra-low carbon and high-purity steels.

Better Control Over Impurities: The vacuum environment allows for better control over the removal of impurities such as hydrogen, nitrogen, and sulfur.

2. Versatility: VD/VOD Furnace is versatile and can be used for wide range of steel grades, including high-alloy and specialty steels.

Disadvantages:

1. Higher Costs: VOD is generally more expensive to operate due to the need for vacuum equipment and higher energy consumption.

2. Complexity: The process is more complex and requires more sophisticated equipment and control systems.

3. Higher Power Requirements: VOD requires significant power, which may be a limitation given your plant’s current power allocation.

Given that your plant does not have an LRF or the power allocation to implement one, AOD might be the more suitable option for your setup. It is cost-effective, requires less power, and is efficient for producing stainless steel, which aligns well with your current capabilities and constraints. However, if your production requires ultra-high purity and better control over impurities, you might need to consider the additional investment and power requirements for VOD.

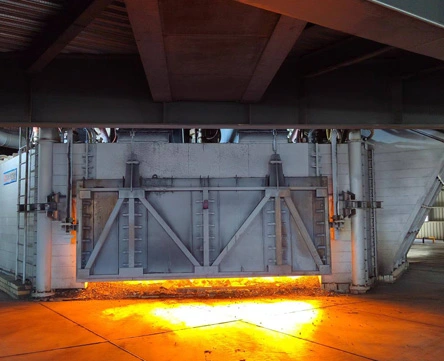

CHNZBTECH, an excellent continuous casting machine supplier, provides products, including the VOD furnace, AOD furnace, and scrap charging bucket, designed for high performance, durability, and efficiency. CHNZBTECH will offer competitive prices, ensuring you get the best value for your money.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa