The process of steelmaking is complicated, and it involves various equipment and stages, one of which is employing a ladle refining furnace (LRF). The LRF furnace in a steel plant is instrumental in refining molten steel and adjusting its chemical composition to align with manufacturing requirements. However, like any industrial equipment, operating a ladle refining furnace in a steel plant requires the utmost level of safety consciousness and adherence to best practices.

For a smooth ladle refining furnace operation process in steelmaking, workers must undergo thorough training to understand the equipment's mechanics, temperature controls, and potential hazards. Effective ladle refining furnace operations rely on proper handling, routine maintenance, and detailed safety protocols to prevent accidents and maximize efficiency. Follow industry-leading ladle refining furnace operation guidelines today to optimize your plant's productivity, safety, and profitability!

Understanding the Ladle Refining Furnace

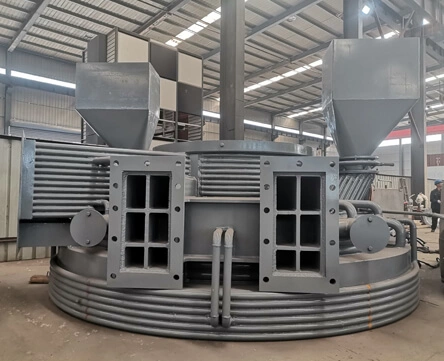

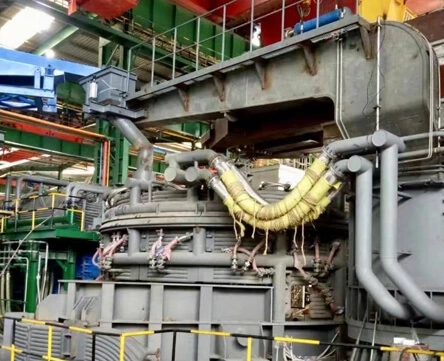

A ladle refining furnace, sometimes simply referred to as a steel ladle, is predominantly used to refine the chemical composition and temperature of molten steel. The ladle refining furnace (LRF) takes a batch of molten steel directly from types of electric arc furnace (EAF) and goes on to desulfurize, deoxidize, and remove unwanted elements like non-metallic inclusions (NMI). This process yields quality steel that hits stringent industry specifications.

Interested in integrating or optimizing a ladle refining furnace in your facility? Using LRF in a steel plant can enhance productivity while maintaining strict quality standards. For steel plants striving for superior refining performance, a ladle refining furnace is an indispensable asset. Partner with a reputable LF refining furnace manufacturer that prioritizes reliability and efficiency.

Safety Protocols for Ladle Refining Furnace Operations

In the interests of workplace safety and to prevent any industrial accidents, it is vital to adhere strictly to the established safety procedures while operating a ladle refining furnace. For instance, in the event of an overflow situation, operators must react instantly and adhere to a predetermined plan. Keeping the path clear of obstacles for quick mass evacuation becomes necessary in such scenarios.

Operating a ladle refining furnace requires strict adherence to safety measures to ensure both efficiency and worker well-being. Personal protective equipment (PPE) such as heat-resistant gloves, safety glasses, footwear, and overalls should always be used when operating or even being in proximity to the ladle refining furnace. Regular maintenance checks are needed to ensure the refining furnace and its supporting gear operate optimally. This includes thermocouples, voltage reels, servo valves, and hydraulic systems. By prioritizing the upkeep of these elements, we can enhance the overall performance of ladle refining furnaces.

Additionally, operators must always steam out and completely dry the ladle before use to eliminate moisture, as traces of it could lead to serious explosions when it comes into contact with molten steel. A well-maintained ladle refining furnace maximizes productivity and worker safety. Upgrade your steel plant with technology backed by trusted steel furnace manufacturers.

Best Practices in Ladle Refining Furnace Operations

In steel manufacturing operations, the goal is to strive for maximum efficiency while also minimizing potential hazards. Key best practices include implementing a rigid training program for all employees handling expensive and potentially dangerous equipment, such as LRFs. Staff should be retrained regularly on fundamentals and new techniques in furnace operation.

It's also a good practice to monitor the furnace’s condition regularly. Predictive and preventive maintenance structures need to be in place to maximize productivity and reduce downtime. Finally, operators must always maintain the prescribed chemical composition of molten steel, ensuring that it falls within regulatory standards. Automated systems should be installed to increase precision and reduce the scope for human error.

The Relevance of Safety and Efficiency in Ladle Refining Furnace Operations

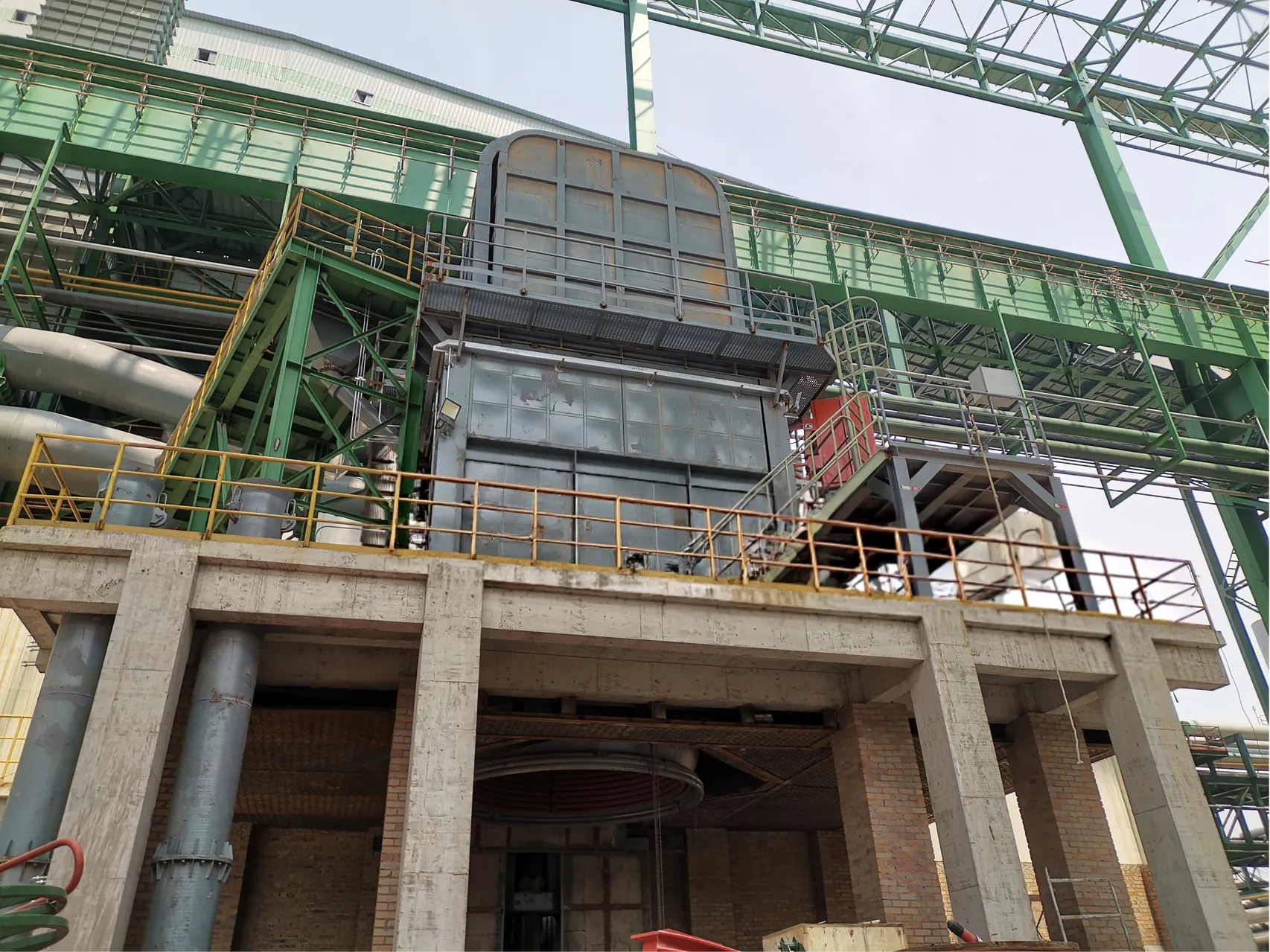

Safe and efficient operation of the ladle refining furnace (LRF) cannot be overemphasized. It promotes a better workplace environment, reduces potential hazards, and most importantly, it boosts overall productivity. While steel manufacturing is a process laden with inherent risks, the efficient and safe operation of a ladle refining furnace can significantly mitigate these dangers while ensuring manufacturing targets are met efficiently, effectively, and under optimal safety conditions.

In conclusion, the ladle refining furnace is an essential machine in steelmaking, and its operation should be well-regulated. Following stringent safety protocols and generating consistent best practices secures not just the equipment's optimal functioning but also the protection of those who operate it. By integrating these crucial elements, a steel plant can boost productivity, foster a safer work environment, and contribute to the smooth-running of the manufacturing process.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa