Argon Oxygen Decarburization (AOD) is revolutionizing the steel industry with its ability to produce cleaner and greener steel. As the demand for sustainable and environmentally-friendly practices increases, steel producers are turning to AOD as a solution to reduce carbon emissions and improve the overall environmental impact of steel production. In this blog, we will explore the significance of AOD and its role in creating a more sustainable steel industry.

What is Argon Oxygen Decarburization?

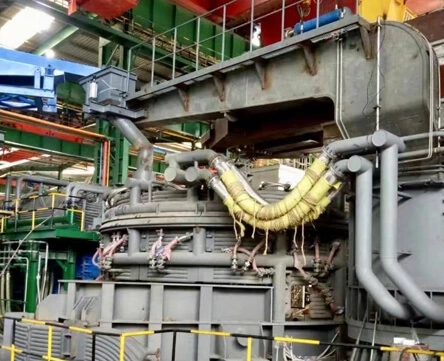

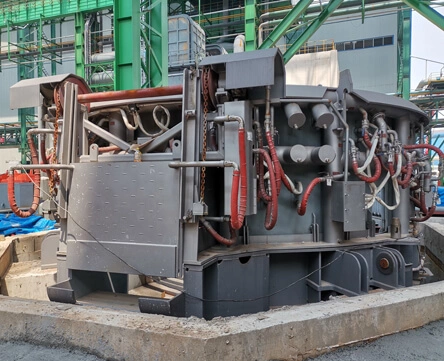

Argon Oxygen Decarburization is a refining process used in steel production to reduce the carbon content in molten steel. It involves injecting a mixture of oxygen and argon gas into the molten steel, which reacts with the carbon, forming carbon monoxide and reducing the carbon content. This process not only removes impurities but also results in lower carbon emissions compared to traditional steel refining methods.

Reduced Carbon Emissions

One of the significant advantages of Argon Oxygen Decarburization is its ability to reduce carbon emissions. By eliminating the need for excessive amounts of carbon-rich materials, such as coal and coke, AOD reduces the overall carbon footprint of the steel industry. This reduction in carbon emissions directly contributes to the fight against climate change and helps to create a more sustainable future.

Improved Energy Efficiency

AOD also enhances energy efficiency in steel production. Traditional steel refining methods require high temperatures and energy-intensive processes, leading to significant energy consumption. On the other hand, AOD operates at lower temperatures, reducing energy requirements and minimizing the environmental impact. This improved energy efficiency not only reduces greenhouse gas emissions but also lowers production costs for steel manufacturers.

Enhanced Steel Quality

In addition to its positive environmental impact, Argon Oxygen Decarburization improves the quality of steel. By removing impurities such as sulfur, nitrogen, and phosphorus, AOD produces cleaner steel with improved mechanical properties. This higher quality steel can be utilized in a wide range of applications, from automotive and construction to aerospace industries, contributing to a more sustainable and durable infrastructure.

Future Perspectives and Integration

As the demand for cleaner steel continues to grow, Argon Oxygen Decarburization will play an increasingly important role in the steel industry. With its significant environmental benefits, AOD is expected to become the standard method for steel refining. Researchers and experts are constantly exploring ways to improve the AOD process further, such as optimizing gas injection techniques and developing new catalysts. The integration of AOD with other sustainable practices, such as renewable energy sources and recycling, will further enhance the overall environmental impact of the steel industry.

Argon Oxygen Decarburization is not only revolutionizing the steel industry but also contributing to a cleaner and greener future. Its ability to reduce carbon emissions, improve energy efficiency, and produce higher quality steel makes it an essential component in the pursuit of sustainable steel production. As the industry continues to embrace AOD and its advancements, we can look forward to a future where steel manufacturing is both environmentally friendly and economically viable.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa