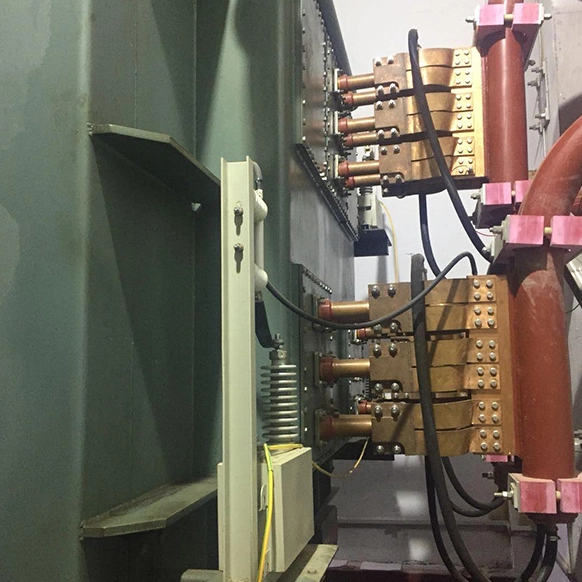

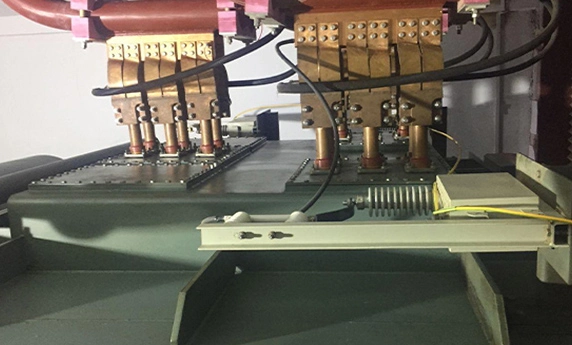

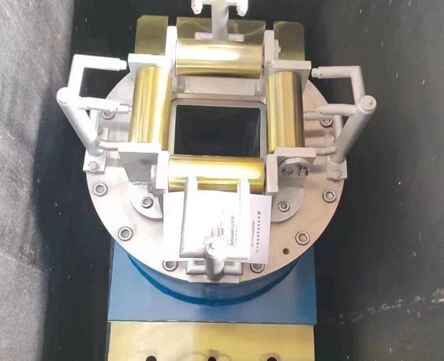

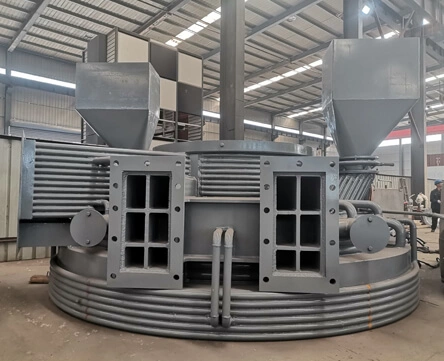

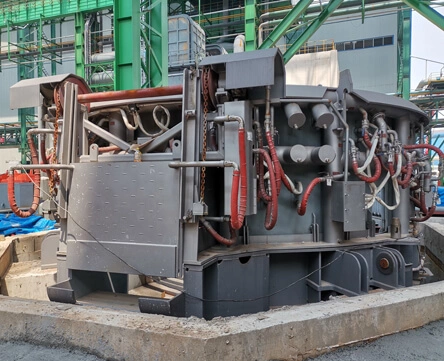

The copper busbar system refers to the high-current line which is rear part of transformer secondary, and the custom copper busbar is composed of water-cooled cable compensator, water-cooled copper tube group, large-section water-cooled cable,electrode arms and graphite electrode. The grounding copper busbar does not includes electrode arms and graphit electrodes.

Copper busbar system also named as high current line refers to secondary side outlet copper pipe of transformer for EAF, LF, SAF, is consists of compensator group, through-wall copper pipe group, water-cooled busbar, water-cooled cable, conductive electrode arm, and graphite electrode etc. Between the beginning end of water-cooled copper bus pipe and secondary outlet copper bus pipe of transformer, using flexible strand cable compensator, may released influence of heat expansion, electro-power for fixed parts, for sustaining points of through-wall copper pipe group, copper grounding bus bar and water- cooled cable all bearing by bracket of non-conduct magnetic stainless steel, also use insulation parts for liner.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa