The VIP series inverter power supply produced by our company has huge advantages in energy conservation compared to traditional KGPS parallel inverter intermediate frequency power supply. This furnace auxiliary equipment can save huge energy consumption in terms of power factor, filtering and smoothing method, and power distribution method.

Newly developed DFI intermediate frequency power supply combines the advantages of IGBT and SCR series inverter technology, making the equipment more energy-efficient and stable.

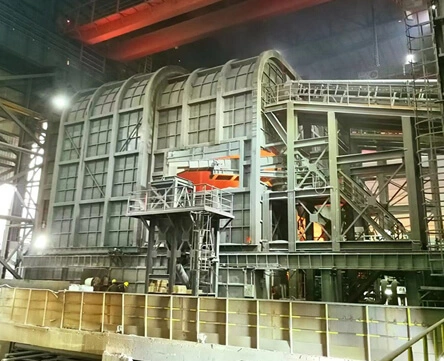

The new steel shell electric furnace body includes: open or closed furnace body, furnace frame, cyclone or annular dust removal cover, furnace cover, tilting furnace oil cylinder, induction ring, magnetic knob, furnace mouth and bottom pouring block. A complete set of stainless steel water inlet distributor, easy to maintain, with a simple and sturdy structure. The new type steel shell electric furnace body has advantages such as better material usage, more reasonable structure, and built-in dust removal cover and hydraulic furnace cover compared to the old type furnace body.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa