On the grand stage of industrial production, electric arc furnace steelmaking production technology has emerged as a cornerstone of the global steel sector, captivating with its unique allure and unparalleled advantages. More than just a steelmaking technique, it stands as a living embodiment of scientific advancement, technological prowess, and environmental stewardship. In this article, our steel furnace manufacturers aim to unravel the enchantment of electric arc furnace steelmaking production technology while illuminating its pronounced merits in terms of innovation, efficiency, and environmental consciousness.

Innovation Unleashed: The Heartbeat of Progress

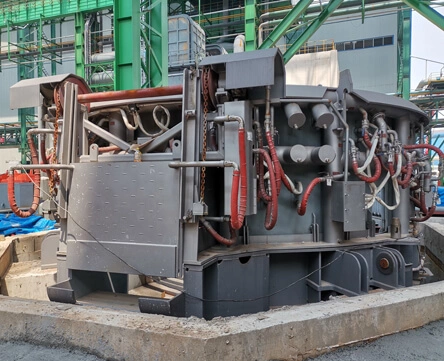

The most captivating facet of electric arc furnace steelmaking production technology resides in its spirit of innovation. This cutting-edge approach fuses traditional steelmaking methodologies with modern technology, birthing an efficient, energy-conserving, and environmentally benign production process. Steelmaking in electric arc furnace types is a driving force behind enhanced steel production efficiency, lowered operational costs, and minimized environmental footprint. It's a transformative blend where innovation meets sustainability, a testament to the industry's evolution towards greener pastures.

Efficiency Redefined: A Race Against Time

Electric arc furnace steelmaking's allure also lies in its exceptional efficiency. By adopting the direct reduction method, this approach significantly enhances steel production efficiency. In stark contrast to traditional converter steelmaking, electric arc furnace steelmaking accomplishes a multitude of production tasks in considerably shorter durations, thus elevating the overall efficiency of steel manufacturing. Burstiness becomes evident here, as steel is created swiftly and resourcefully, aligning seamlessly with the manufacturer's objectives.

Environmental Guardianship: Forging a Greener Tomorrow

A prominent charm of electric arc furnace steelmaking production technology is its commendable environmental stewardship. This method champions eco-friendliness, effectively curbing environmental pollution. Unlike other types of steel making furnaces, electric arc furnace steelmaking scarcely generates copious waste gases or wastewater during production. Moreover, it actively engages in recycling, repurposing waste materials and paving the way for resource regeneration—a testament to its commitment to sustainable practices.

A Vision for Tomorrow: The Ongoing Evolution

In summation, electric arc furnace steelmaking production technology stands as a beacon of progress, innovation, and environmental responsibility in the global steel industry. Its penchant for innovation, unmatched efficiency, and dedication to environmental preservation position it as a pivotal force propelling the steel sector into a new era. With each stride forward, electric arc furnace steelmaking production technology solidifies its role as a vital contributor to the global steel production landscape. As time unfolds, our faith in its capacity to mature and advance further grows stronger, promising an even brighter future for steel manufacturing on a global scale.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa