The AOD furnace, standing for Argon Oxygen Decarburization furnace, is a vital component in the stainless steel manufacturing process. This sophisticated technology plays a pivotal role in refining stainless steel, enhancing its quality, and meeting stringent industry standards. In this article, we unravel the workings of the AOD furnace, shedding light on its process and operation.

The AOD furnace process is integral to the production of stainless steel, particularly in the manufacturing of low-carbon and low-silicon grades. The primary objective of the AOD process is to reduce the carbon content of the molten metal while simultaneously removing impurities such as sulfur, phosphorus, and nitrogen, thus refining the steel to meet desired specifications.

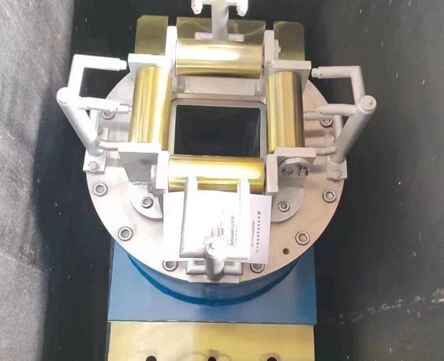

Operationally, the AOD furnace operates under controlled conditions of temperature, atmosphere, and chemistry to facilitate efficient decarburization and desulfurization of the molten metal. The furnace chamber is typically lined with refractory materials capable of withstanding high temperatures and corrosive environments.

The AOD furnace operation begins with the charging of the furnace with a mixture of molten iron and scrap steel, along with selected alloying elements to achieve the desired composition. Once the furnace is charged, an inert gas, usually argon, is introduced into the chamber to create a protective atmosphere and prevent oxidation of the metal.

Simultaneously, oxygen is injected into the molten metal bath to oxidize the impurities present, primarily carbon. The oxygen reacts with the carbon, forming carbon monoxide and carbon dioxide, which are then removed as gases. The addition of oxygen also promotes the removal of other undesirable elements, such as sulfur and phosphorus, through the formation of volatile oxides.

Throughout this secondary refining process, precise control of temperature, gas flow rates, and chemical composition is maintained to ensure optimal refining efficiency and product quality. Advanced automation and monitoring systems facilitate real-time adjustment of process parameters, allowing for fine-tuning and optimization based on specific alloy requirements.

CHNZBTECH, one of the leading steel furnace manufacturers of metallurgical equipment and solutions, offers state-of-the-art AOD furnace technology tailored to the needs of stainless steel producers worldwide. With a focus on innovation and reliability, CHNZBTECH's AOD furnaces boast advanced features such as energy efficiency, reduced emissions, and enhanced operational flexibility, enabling manufacturers to achieve higher productivity and product consistency.

In conclusion, the AOD furnace plays a critical role in the production of high-quality stainless steel, offering a reliable and efficient means of refining molten metal to meet exacting specifications. Through precise control of process parameters and advanced technology, companies like CHNZBTECH continue to drive advancements in AOD furnace technology, ensuring the sustainability and competitiveness of the stainless steel industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa