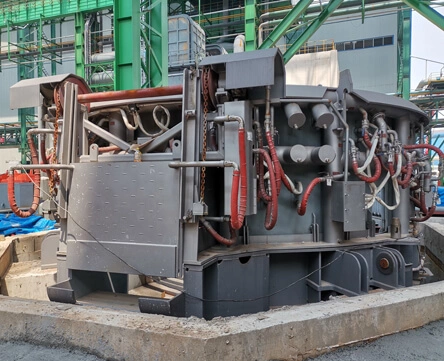

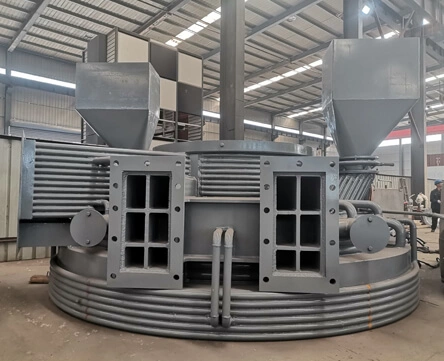

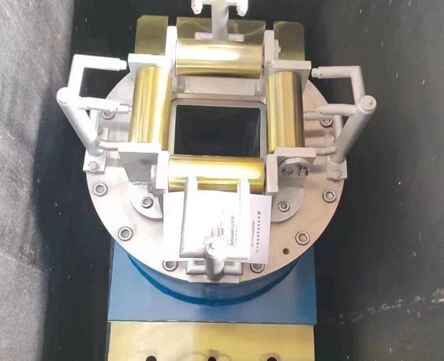

The Electrode heads and contact pads provide the final connection between the power supply and the graphite electrode. They are exposed to extreme mechanical conditions (vibration, torsion etc.) and thermal cycling and as a result are the weakest link in the secondary circuit. Traditional electrode holders are either cast or fabricated from copper plates. These furnace spare parts are smaller and incorporate only the electrode contact area. In traditional electrode holders, the electrode is pushed forward into the contact area. In the case of contact pads, the electrode is pulled back with steel housing equipment to make contact with the pad.

The current transfer between the contact pad and the electrode occurs in the lower 3 or 4 inches. Proper clamping of the two electrode voltage clamp for is a necessity in order to prevent arcing between the electrode and the contact area. Any dirt build-up in this area will result in resistance to current flow and will cause over-heating and damage to the electrode holder/contact pad. Typically cooling water requirements will vary from 2 to 40 gallons per minute depending on the electrode size, water quality, clamping force and maintenance of a clean contact area. The contact area of the 2 electrode voltage clamp should be cleaned regularly to remove oxidation, carbon build-up and other material build-up in this area.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa