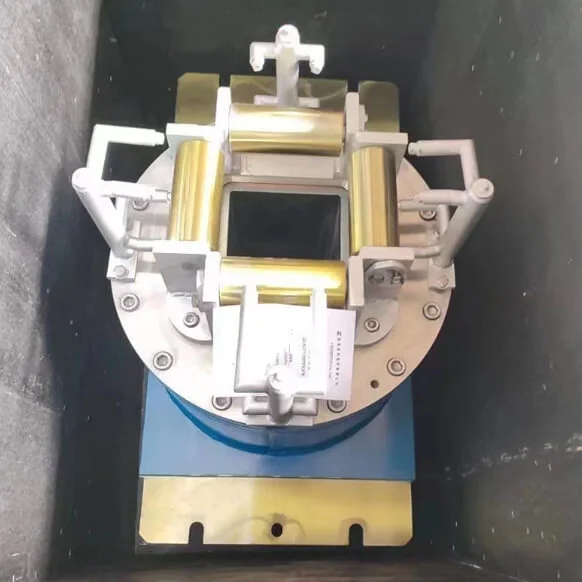

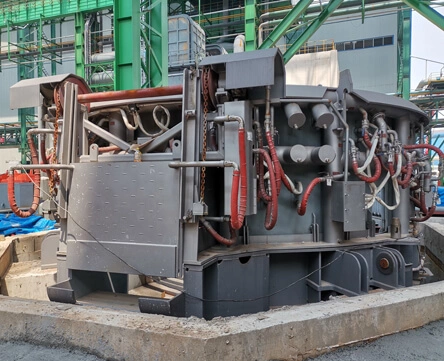

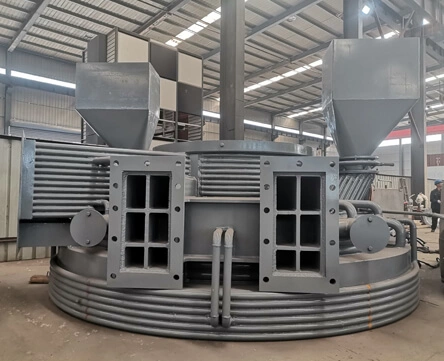

Copper mold is a groove shaped container with a jacket on the wall or a snake tube inside, used to heat or cool the solution in the tank. The crystallization tank can be used as an evaporation crystallizer or a cooling crystallizer. To improve the production intensity of crystals, an agitator can be added in the tank. Crystallization tanks can be used for continuous or intermittent operations. The crystals obtained through intermittent operation are relatively large, but they are prone to forming clusters and entraining the mother liquor, which affects the purity of the product. This crystallizer has a simple structure and low production intensity, making it suitable for the production of small batch products such as chemical reagents and biochemical reagents.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa