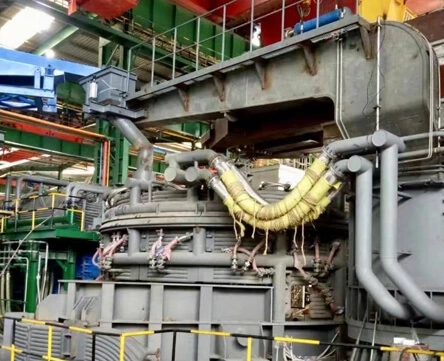

Top EAF charging is convention type, from 0.5t to 200t, each capacity requires a bucket charge from the top. The first step in any EAF tap-to-tap cycle is "charging" into the scrap. The EAF roof and electrodes are raised and are swung to the side of the electric arc furnace charging furnace to allow the scrap EAF charging crane to move a full bucket of scrap into place over the EAF charging furnace. The bucket bottom is usually a clam shell design - i.e. the bucket opens up by retracting two segments on the bottom of the bucket. The scrap falls into the EAF charging furnace and the scrap crane removes the scrap bucket. The roof and electrodes swing back into place over the electric arc furnace charging furnace.

Electric arc furnace that uses the high temperature produced by electrode arc to melt ore and metal, DRI, HBI. When gas discharge forms an arc, this energy is very concentrated, and the temperature of the arc zone is above 3000 ℃. For metal smelting, electric arc furnaces have greater flexibility in the process compared to other steel-making furnaces, effectively removing impurities such as sulfur and phosphorus. The electric arc furnace charging furnace temperature is easy to control, and the equipment occupies a small area, making them suitable for the melting of high-quality alloy steel.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa