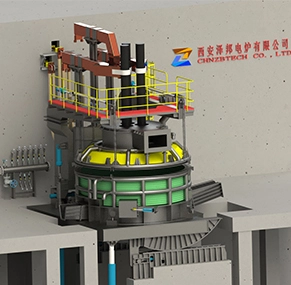

Submerged Arc Furnaces (SAF) find diverse applications across various industries, primarily in the production of different iron alloys. These applications include the production of ferrochromium, ferro-nickel, ferromanganese, silicomanganese, ferro-niobium, and titanium iron ore (TiO2 slag). Additionally, SAFs offer potential for waste recycling.

Initially, iron alloys were exclusively produced in specialized high furnaces, yielding pig iron with varying amounts of silicon, chromium, and manganese. The type of melting and metallurgical equilibrium determined the carbon content of these alloys. These types of steel making furnaces stand out as qualified equipment for alloy production due to their precise temperature control and adjustment of different reduction potentials. The establishment of independent ferroalloy industries has met the growing demands of today's steel industry over time.

The powerful competition in this field is mainly achieved through the installation of advanced high-power smelting units in SAFs. Currently, over 99% of ferroalloy and TiO2 production takes place in alternating current SAFs.

Developments in large electrode systems, advanced transformer technology, and new furnace construction principles have made it possible to design large-capacity rectangular SAFs with dimensions reaching up to 36 meters in length and 17 meters in width. From a technical perspective, even larger units are possible, but their economic feasibility must be carefully examined.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa