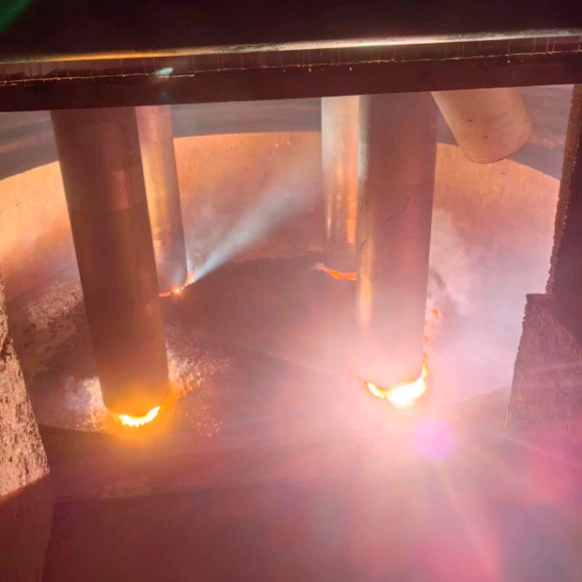

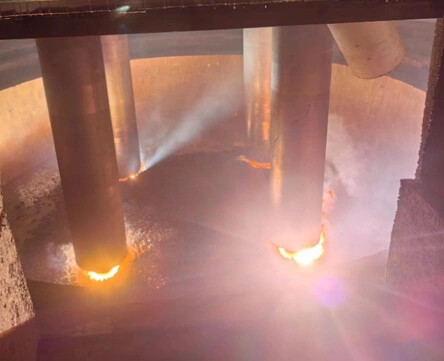

DC submerged arc furnace is superior to AC arc in stability and single direction, which has great benefits for heat transfer in metallurgical processes. Theoretical analysis indicates that replacing AC current with DC current is a significant technological innovation measure. Due to the absence of zero crossing of DC current, the stability of the arc is improved, and the interference to the power grid is reduced accordingly. The method of using direct current to smelt metal in a direct current submerged arc furnace is basically the same as that of an alternating current arc furnace. However, due to the high anode heat on the charging side, the electric heating efficiency of the DC arc is high. Using a controllable thyristor static converter as the power supply for the DC submerged arc furnace, the AC power supply can be converted into DC. Practices of the DC submerged arc furnace ferroalloys production confirmed the advantages of the DC submerged arc furnace process including energy saving and other economic benefits.Compared with AC furnace, except for yield is the same, specific energy reduces.

The structure of DC submerged arc furnace is basically similar to that of AC submerged arc furnace. The main electrical equipment includes rectifier transformer, rectifier cabinet, high and low voltage electrical equipment and electric control system. The main mechanical equipment includes single-phase self baking electrodes or graphite electrodes, electrode holders, electrode lifting structures and electrode hold and release devices, semi enclosed low smoke hoods, conductive furnace bodies, hydraulic systems, water cooling systems, feeding devices, and smoke exhaust systems.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa