In the realm of ferro alloy production, the submerged arc furnace (SAF) plays a pivotal role, and CHNZBTECH stands out as a trailblazer in harnessing the capabilities of electric submerged arc furnaces for efficient and high-quality ferro alloy manufacturing.

Electric Submerged Arc Furnace:

CHNZBTECH's commitment to innovation is exemplified in its utilization of ferro alloy electric arc furnace. This method involves the use of electric energy to generate intense heat, melting raw materials submerged in a bath of molten slag. The unique submerged aspect enhances the efficiency of the smelting process, ensuring thorough alloy composition control.

SAF Submerged Arc Furnace:

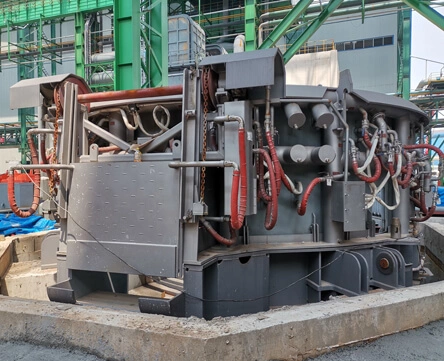

Specifically designed for ferro alloy production, the SAF submerged arc furnace at CHNZBTECH integrates advanced technology to achieve optimal results. The furnace, one of types of steel making furnaces, is engineered to handle a variety of raw materials, including ore, fluxes, and reducing agents. The SAF process allows for the precise control of temperature and chemical composition, resulting in high-quality ferro alloys.

CHNZBTECH's SAF submerged arc furnace is distinguished by its efficiency in reducing raw materials to their metallic state. The smelting process is carefully monitored and controlled through advanced automation systems, ensuring consistency in alloy quality. The company's SAF technology is aligned with the industry's demand for ferro alloys with specific metallurgical properties.

Advanced Engineering and Design:

CHNZBTECH, one of the leading submerged arc furnace suppliers in China, places a strong emphasis on advanced engineering and design in its submerged arc furnaces. The furnaces are meticulously crafted to optimize performance, taking into account factors such as heat distribution, material selection, and structural integrity. This commitment to precision ensures that CHNZBTECH's SAF submerged arc furnaces meet or exceed the stringent standards set by the ferro alloy industry.

Innovative Solutions for Industry Challenges:

Ferro alloy production comes with its unique challenges, and CHNZBTECH addresses these challenges with innovative solutions. From adapting to varying raw material compositions to ensuring energy efficiency, the company's SAF submerged arc furnaces are designed to overcome industry hurdles. CHNZBTECH's commitment to innovation positions it as a reliable partner for industries relying on high-quality ferro alloys.

Conclusion:

CHNZBTECH's pioneering approach to submerged arc furnace technology for ferro alloy production reflects its dedication to excellence. The integration of electric submerged arc furnaces and SAF technology showcases the company's commitment to efficiency, precision, and innovation. As a key player in the metallurgical sector, CHNZBTECH continues to lead the way in delivering advanced solutions that meet the evolving demands of ferro alloy production on a global scale.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa