Stainless steel, renowned for its corrosion resistance, durability, and aesthetic appeal, is a ubiquitous material in various industries, from construction to automotive and beyond. At the heart of stainless steel production lies the electric arc furnace (EAF), a versatile and efficient technology revolutionizing steelmaking processes. In this article, we explore the role of EAFs in stainless steel production and the contributions of CHNZBTECH, a leading electric arc furnace China provider, in advancing this transformative technology.

The electric arc furnace for steelmaking represents a departure from traditional methods, offering several advantages, including flexibility in raw material selection, reduced energy consumption, and lower environmental impact. Unlike the conventional blast furnace route, which relies on iron ore and coke, EAFs can utilize a wide range of scrap steel, including both ferrous and non-ferrous materials, thus promoting recycling and resource conservation.

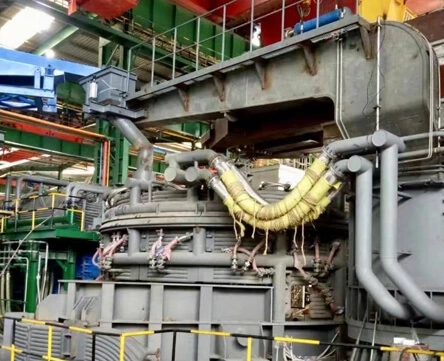

Electric arc furnace steelmaking involves the use of high-voltage electric arcs to melt scrap steel and other alloying elements, such as chromium and nickel, in a refractory-lined furnace. The intense heat generated by the electric arcs, reaching temperatures of up to 3,000 degrees Celsius, facilitates rapid melting of the metal charge, while the presence of oxygen and other reactive gases helps remove impurities and control the chemical composition of the molten steel.

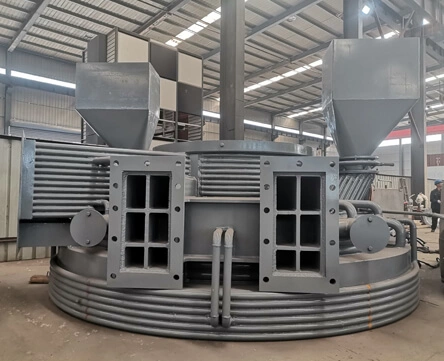

CHNZBTECH stands at the forefront of EAF charging technology, offering innovative solutions tailored to the specific requirements of stainless steel producers worldwide. With a focus on efficiency, sustainability, and performance, CHNZBTECH's electric arc furnaces integrate advanced features such as advanced electrode control systems, automated charging mechanisms, and real-time process monitoring capabilities.

The utilization of electric arc furnace steelmaking by CHNZBTECH enables stainless steel manufacturers to achieve greater flexibility in production, allowing for rapid adjustments in output and alloy composition to meet changing market demands. Furthermore, EAFs offer significant energy savings compared to traditional steelmaking methods, contributing to cost reduction and environmental sustainability.

In addition to providing state-of-the-art equipment, CHNZBTECH offers comprehensive support services, including technical assistance, maintenance, and training programs, to ensure the optimal performance and reliability of its electric arc furnaces. By partnering with CHNZBTECH, stainless steel producers gain access to cutting-edge technology and expertise, empowering them to stay competitive in today's dynamic marketplace.

In conclusion, among types of furnaces in steel making, electric arc furnaces have emerged as a cornerstone of modern stainless steel production, offering efficiency, flexibility, and environmental sustainability. CHNZBTECH's commitment to innovation and customer satisfaction has positioned it as a trusted partner for stainless steel manufacturers seeking to embrace EAF technology and unlock new opportunities for growth and success in the global marketplace.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa