Electric arc furnaces (EAFs) stand as indispensable tools in modern steelmaking, offering flexibility, efficiency, and environmental sustainability. Central to the operation of EAFs is the charging process, where raw materials are introduced into the furnace to initiate steel production. In this article, we delve into the intricacies of electric arc furnace charging, exploring its significance, challenges, and innovative solutions designed by companies like CHNZBTECH, a prominent player in industrial electric arc furnace technology.

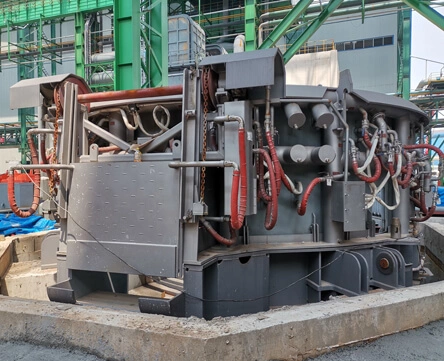

The design of types of electric arc furnace plays a crucial role in optimizing the charging process. EAFs typically consist of a cylindrical vessel lined with refractory materials, equipped with graphite electrodes and advanced control systems. The furnace design facilitates efficient heat transfer, chemical reactions, and mixing of materials during the steelmaking process.

Industrial electric arc furnaces are capable of processing a wide range of raw materials, including scrap steel, pig iron, direct reduced iron (DRI), and various alloying agents. The charging process begins with the loading of scrap steel and other feed materials into the furnace, ensuring a balanced mix of metallic and non-metallic components to achieve the desired steel chemistry and quality.

CHNZBTECH, one of the leading steel furnace manufacturers in China, specializes in the design and manufacture of types of steel making furnaces tailored to the specific needs of steel producers worldwide. With a focus on innovation and reliability, CHNZBTECH's EAFs feature advanced charging systems designed to maximize efficiency and productivity while minimizing energy consumption and environmental impact.

One of the key challenges in electric arc furnace charging is achieving optimal material distribution and utilization within the furnace chamber. Uneven charging or improper placement of materials can lead to inconsistent heating, inefficient melting, and reduced quality of the final steel product. To address this challenge, CHNZBTECH integrates sophisticated charging systems with automated controls and sensors, allowing for precise manipulation of material flow and distribution during the charging process.

Furthermore, CHNZBTECH's electric arc furnace designs incorporate advanced features such as preheating stations, scrap cutting and handling equipment, and scrap bucket charging systems, enabling seamless integration of different raw materials and enhancing overall furnace performance.

By leveraging cutting-edge technology and engineering expertise, CHNZBTECH empowers steel producers to optimize their electric arc furnace charging operations, thereby improving productivity, reducing operating costs, and enhancing product quality. Through ongoing research and development efforts, the company continues to innovate and refine its charging systems to meet the evolving needs of the steel industry.

In conclusion, electric arc furnace charging is a critical aspect of steelmaking, influencing process efficiency, product quality, and environmental sustainability. CHNZBTECH's commitment to innovation and customer satisfaction positions it as a trusted partner for steel producers seeking to enhance their EAF operations and achieve success in today's competitive marketplace.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa