Induction Furnace Melting Process:

The induction furnace melting process is a revolutionary method employed in the metallurgical industry for the efficient melting and refining of metals. Unlike traditional furnaces, induction furnaces utilize electromagnetic induction to generate heat directly within the metal charge. This process offers a rapid and precise means of achieving high temperatures, making it a preferred choice for various metal melting applications.

How Induction Melting Furnace Works:

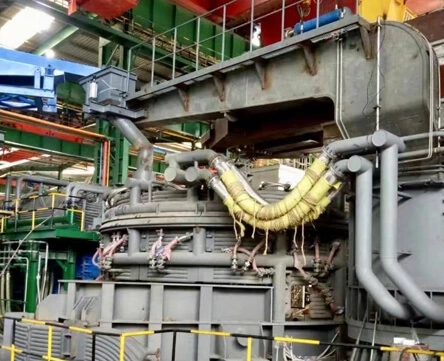

The fundamental principle behind the induction melting furnace lies in electromagnetic induction. The process begins with the placement of the metal charge, typically in the form of scrap or raw materials, within the furnace's crucible. The induction coil surrounding the crucible carries alternating current (AC), creating a rapidly changing magnetic field. As the metal charge is exposed to this magnetic field, eddy currents are induced within the metal, generating intense heat due to electrical resistance.

The heat generated through electromagnetic induction causes the metal charge to reach its melting point, resulting in the efficient melting and refining of the material. Induction furnaces offer precise temperature control, allowing for the production of high-quality alloys with minimal energy consumption.

CHNZBTECH and Induction Furnace Technology:

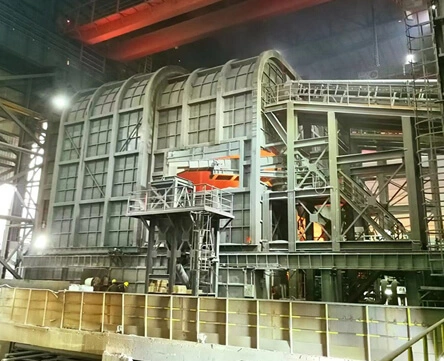

CHNZBTECH has been a pioneering force in the advancement of induction furnace technology. The company is recognized for its expertise in designing and manufacturing innovative induction melting solutions. Their induction furnaces are engineered to deliver optimal performance, energy efficiency, and versatility in various metallurgical processes.

CHNZBTECH's induction furnace technology incorporates state-of-the-art features, including advanced control systems, efficient cooling mechanisms, and robust construction. These elements contribute to the reliability and longevity of their induction furnaces, making them a trusted choice for industries involved in metal melting and alloy production.

In addition to providing cutting-edge technology, CHNZBTECH offers comprehensive support and customization options, ensuring that their induction furnaces meet the specific needs of each client. This commitment to excellence has established CHNZBTECH as a prominent player in the global market for induction furnace solutions.

In conclusion, the induction furnace melting process represents a significant leap forward in metallurgical practices, offering efficiency, precision, and versatility. CHNZBTECH's contributions to the field underscore the importance of innovation in advancing induction furnace technology, making it a cornerstone in modern metal melting and refining operations.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa