VD furnace and the improvement of material purity

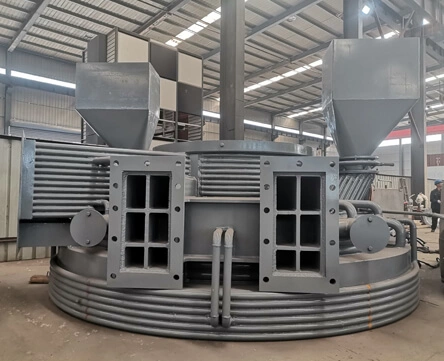

VD furnace, i.e. vacuum degassing furnace, is a key equipment in the metal refining process. Its working principle is to remove gases and non-metallic inclusions in the metal melt through heating and degassing treatment under vacuum environment. This process significantly improves the purity of the metal and reduces internal defects, which in turn improves the overall properties of the material.

Increased purity means a more uniform distribution of stresses within the material and enhanced mechanical properties such as strength and toughness. At the same time, the high purity of the material in the corrosion resistance, oxidation resistance and other aspects of the material also shows more excellent performance, extending the service life of the material.

VD furnace optimization of the chemical composition of the material

In addition to enhance the purity, VD furnace can also accurately control the chemical composition of the molten metal. By adjusting the proportion of alloying elements added and degassing conditions, VD furnace can optimize the chemical composition of the material to meet the special needs of different applications on the material properties.

For example, in the production of alloy steel, the VD furnace is able to precisely control the content of carbon, silicon, manganese and other elements to obtain alloy steel with specific mechanical properties and corrosion resistance. This optimization of chemical composition not only improves the performance of the material, but also expands its scope of application.

The VD furnace to improve the organization of the material structure

VD furnace secondary refining process can also improve the organizational structure of the material. In a vacuum environment, the atomic activity in the metal melt is enhanced, which is conducive to the formation of a more uniform, dense crystal structure. This structural improvement allows the material to disperse stresses more uniformly when subjected to force, improving the material's fatigue and fracture resistance.

In addition, the refining process in the VOD furnace eliminates residual stresses in the material, reducing problems such as cracking and deformation caused by stress concentrations. This helps to improve the processing performance and yield of the material.

The VD furnace to promote the overall improvement of material properties

In summary, the VD furnace by enhancing the purity of the material, optimize the chemical composition and improve the organizational structure and other aspects of the role, to achieve the overall enhancement of material properties. This enhancement is not only reflected in the mechanical properties, corrosion resistance and oxidation resistance of the material, but also in the processing performance and service life of the material.

It is worth mentioning that CHNZBTECH also shows unique brand advantages in the field of electric steel furnace for sale. With its advanced technology, strict quality control and continuous innovation ability, the company provides the steel industry with highly efficient, environmentally friendly and energy-saving smelting equipment.CHNZBTECH's electric steel furnace is able to accurately control the chemical composition and temperature of the steel during the smelting process, so as to obtain high-quality and high-performance steel products. This advantage makes CHNZBTECH stand out in the fierce market competition and become the industry leader.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa