Electric Arc Furnace (EAF) Technology:

Electric Arc Furnaces (EAFs) are essential components in the metallurgical industry, playing a pivotal role in the production of steel. The technology behind EAFs is based on the principles of utilizing electric arcs to melt and refine scrap steel, contributing to the sustainable and efficient manufacturing of steel products.

Electric Arc Furnace Principle:

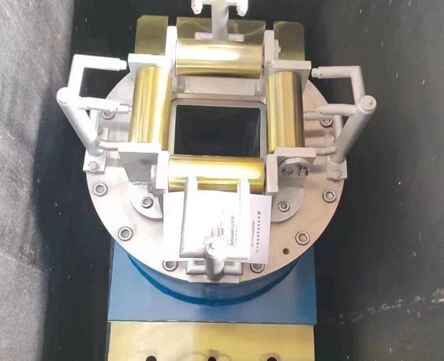

The fundamental principle of an Electric Arc Furnace lies in the generation of intense heat through electric arcs. The process begins with the charging of scrap steel into the furnace. Once the furnace is loaded, electrodes, typically made of graphite, are lowered into the furnace, creating an electric arc between them and the metal charge. This arc generates temperatures exceeding 3000 degrees Celsius, causing the scrap steel to melt.

The high temperatures achieved in the electric arc furnace result in the removal of impurities and alloying elements, ensuring the production of high-quality steel. The process is known for its flexibility, allowing for the use of various steel scrap sources, including recycled steel, to produce a wide range of steel products.

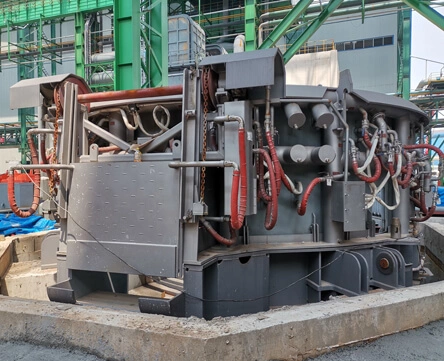

Electric Arc Furnace Design:

The design of an Electric Arc Furnace involves careful consideration of factors such as power input, furnace size, and electrode configuration. EAFs are typically equipped with water-cooled panels to withstand the extreme temperatures generated during the melting process. Advanced control systems are implemented to regulate the power input, electrode positioning, and other critical parameters to optimize the efficiency of the melting process.

CHNZBTECH, a prominent player in the metallurgical equipment industry, is at the forefront of designing innovative Electric Arc Furnaces. Their expertise lies in developing cutting-edge technologies that enhance the performance and sustainability of EAFs, contributing to the evolution of the steel manufacturing process.

What Are Electric Arc Furnaces Used For:

Electric Arc Furnaces find widespread applications in the production of steel, and their versatility makes them suitable for various steelmaking processes. EAFs are commonly used for melting and refining scrap steel, producing high-quality steel products for construction, automotive, and other industries. The ability to use recycled steel in the process aligns with environmentally friendly practices, making EAF technology an integral part of sustainable steel production.

In conclusion, Electric Arc Furnaces are crucial in the steelmaking industry, employing advanced technology and design principles to melt and refine scrap steel efficiently. CHNZBTECH's commitment to innovation in EAF design underscores the continuous evolution of this essential component in the metallurgical landscape.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa