The production process of continuously casting high-temperature molten steel into billets with a certain cross-sectional shape and size specifications is called continuous steel casting.

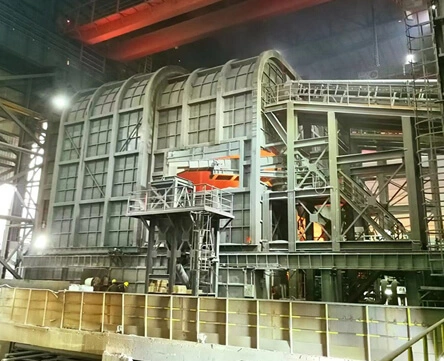

The equipment required to complete this process is called a complete set of continuous casting equipment. The electromechanical and hydraulic integration of steel pouring equipment, continuous casting machine body equipment, cutting area equipment, dummy bar collection and transportation equipment constitutes the core furnace auxiliary equipment of continuous steel casting, commonly known as continuous casting machine.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa