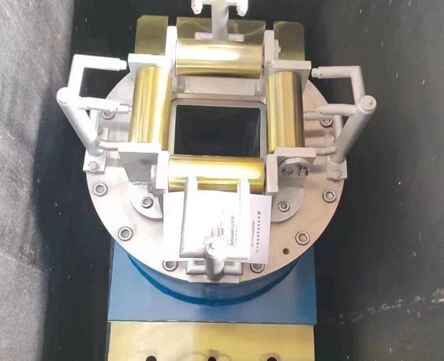

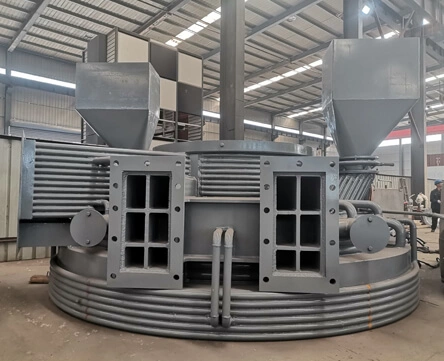

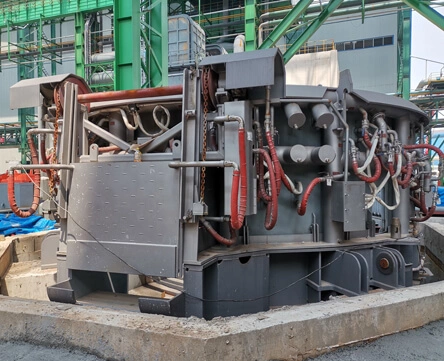

The carbon-oxygen lance mainly refers to the EAF smelting, generally referring to the carbon-oxygen lance at the EAF furnace door, as well as the furnace wall carbon-oxygen burners also called KT lance. The EAF electric arc furnace door carbon-oxygen lance manipulator is equipped with two water-cooled nozzles, some with two water-cooled oxygen lances, and some with combination oxygen lances.

The former consists of two oxygen lances arranged around, one is a Laval supersonic oxygen lance and the other is a carbon lance used for direct hole carbon powder spraying; The latter is equipped with two spray lances arranged above and below the overall lance, with a supersonic oxygen lance below, which is also a Laval nozzle, and a carbon lance above.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa