CHNZBTECH, a global innovator in metallurgical equipment manufacturing, has completed the export of advanced copper water-cooled components and arc furnace center covers to a leading Egyptian steel producer. These mission-critical parts, designed for electric arc furnace (EAF) systems, aim to address extreme thermal challenges while boosting productivity in steelmaking operations.

Innovative Cooling Technology for Demanding Environments

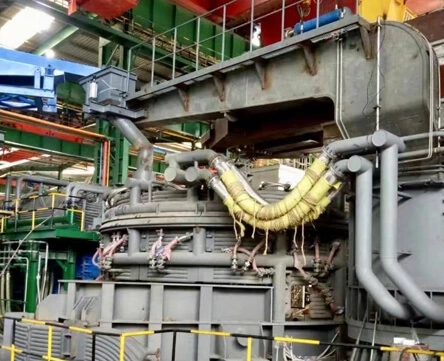

The shipment includes two flagship products:

1. High-Conductivity Copper Water-Cooled Rings

Crafted from premium oxygen-free copper (C10100) for unmatched thermal conductivity.

Engineered with patented channel designs to optimize coolant flow, achieving 30% faster heat dissipation compared to conventional models.

Extended lifespan of up to 18 months under continuous 1,600°C furnace conditions.

2. Reinforced Furnace Center Covers

Multi-layered structure combining steel alloy armor and ceramic insulation for 360° heat shielding.

Modular design allows rapid replacement, minimizing furnace downtime during maintenance.

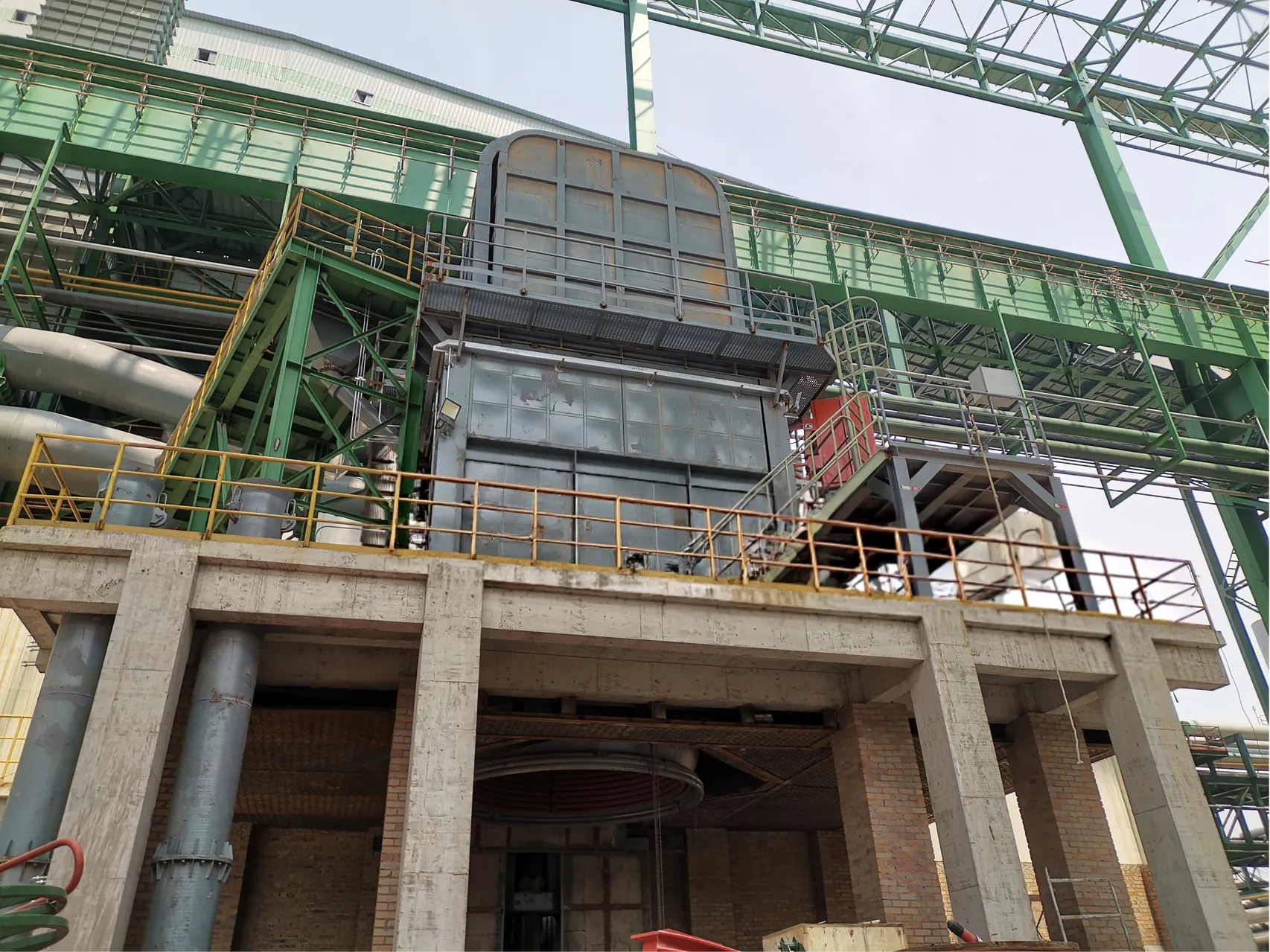

Driving Egypt’s Steel Industry Modernization

The Egyptian client, a state-owned enterprise undergoing facility upgrades, selected CHNZBTECH after rigorous testing of prototypes. The components will be integrated into a new-generation EAF line aimed at increasing annual output by 15% while reducing energy consumption. With decades of expertise as one of the trusted EAF manufacturers, we provide innovative solutions tailored to various operational requirements.

Looking Ahead

With this delivery, CHNZBTECH, one of the excellent steel furnace manufacturers, strengthens its role as a key enabler of Africa’s steel sector transformation. The company is currently collaborating with multiple North African clients on AI-driven smart furnace retrofits, signaling deeper technological partnerships in the region.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa