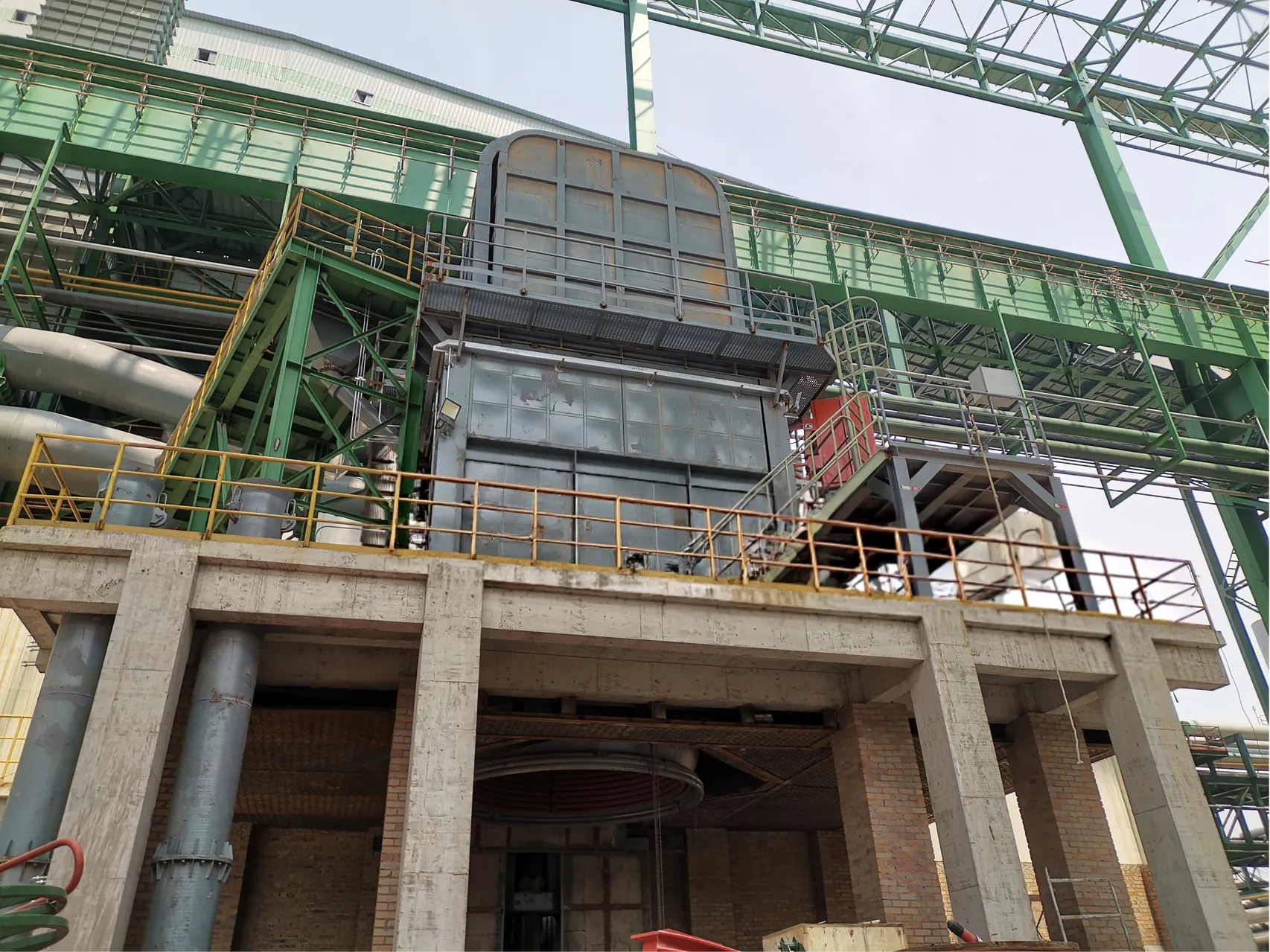

CHNZBTECH, a leading Chinese metallurgical equipment manufacturer, and Italy’s TENOVA, a global metallurgical giant, jointly announced the successful first tapping of the CONSTEEL60t electric arc furnace (EAF) customized for a top Turkish steel group.

Utilizing world-leading continuous charging technology, CHNZBTECH, one of the reliable steel furnace manufacturers, played a pivotal role in the project’s design and manufacturing, exclusively supplying four core systems: the consumable door manipulator, integrated hydraulic power unit, intelligent oxygen valve station, and electric control system. This milestone underscores the growing influence of Chinese metallurgical technology in European markets.

CHNZBTECH’s subsystems feature groundbreaking designs:

Equipped with high-temperature-resistant silicon carbide-coated arms, it withstands 1,200°C radiant heat. Laser vision positioning enables automatic slag removal and door maintenance, reducing labor costs by 70% and achieving SIL-3 safety certification.

Integrated with digital variable-frequency pumps and AI energy optimization algorithms, it cuts energy use by 35% compared to traditional systems, supporting remote diagnostics and adaptive pressure control for CONSTEEL’s continuous feeding process.

Multi-stage closed-loop flow control ensures oxygen injection accuracy within ±1.5%, working with TENOVA’s metallurgical models to optimize dynamic decarbonization and reduce oxygen consumption per ton of steel by 12%.

Built on an industrial IoT framework, it integrates data from 12 subsystems (smelting, dust removal, water cooling, etc.) and streams key parameters to TENOVA’s cloud-based expert database, enabling digital twin optimization.

Client Testimonial: Cross-Border Collaboration Sets Industry Standard

The Turkish client’s technical director remarked during the commissioning ceremony:

“CHNZBTECH’s manipulator eliminated the need for furnace cooling during door maintenance, and their control system’s compatibility with TENOVA’s platform exceeded expectations. This ‘European design + Chinese innovation’ model redefines localized service efficiency.”

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa