What is LRF in Steel Plant?

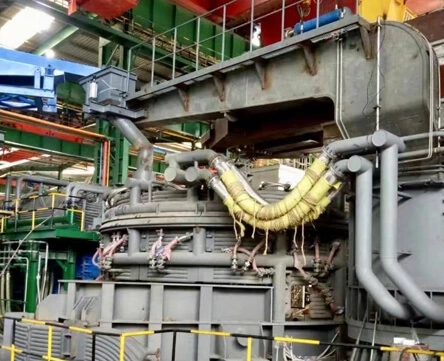

In modern steelmaking operations, the LRF furnace, or Ladle Refining Furnace, plays a crucial role in improving the quality and consistency of molten steel. After the steel is melted in an Electric Arc Furnace (EAF) or Basic Oxygen Furnace (BOF), it often contains residual impurities and non-uniform composition. The LRF furnace is designed to perform secondary refining, a vital step in the LRF steel making process that enhances steel purity and achieves precise control over its chemical and thermal properties. By using electric arc heating combined with argon stirring and controlled slag formation, the furnace ensures the removal of unwanted inclusions and the homogenization of the steel bath. The result is steel that meets demanding specifications for strength, ductility, and surface finish — qualities that define the excellence of modern metallurgical production.

How the LRF Furnace Enhances the Quality of LRF Steel Making

The LRF furnace improves steel refining through advanced temperature and composition control. In LRF steel making, the furnace maintains optimal thermal stability, preventing excessive oxidation and ensuring uniform heat distribution throughout the ladle. The process allows metallurgists to make precise adjustments to carbon, sulfur, and phosphorus levels while also enabling the controlled addition of alloying elements. This precise control ensures steel with improved mechanical properties and microstructural uniformity. CHNZBTECH's LRF systems are engineered with advanced automation and 3D modeling design, which enhances refining efficiency and minimizes process variability. Through these innovations, the LRF furnace has become an indispensable link between the melting furnace and the continuous casting machine, ensuring that every ton of steel meets the highest metallurgical standards.

Why Is the LRF Furnace So Important in the Steel Industry?

The importance of the LRF furnace lies in its ability to stabilize steel quality and reduce inclusions before casting. Without the refining stage, even small variations in temperature or composition could lead to internal defects in the final steel product. In LRF steel making, the furnace functions as a precision refining unit, ensuring that each melt achieves consistent chemical homogeneity. It also allows the steelmaker to reheat the steel without reintroducing impurities, maintaining both thermal efficiency and metallurgical control. The controlled atmosphere inside the LRF minimizes oxidation and nitrogen absorption, resulting in cleaner and stronger steel. CHNZBTECH's innovations in refining systems have made its furnaces widely used in the production of high-quality steels for applications such as automotive components, heavy machinery, and construction frameworks, where precision and performance are essential.

LRF Furnace vs Other Refining Systems in Modern Steelmaking

When comparing the LRF furnace to other refining methods like the VOD or AOD systems, its versatility and precision stand out. While vacuum systems specialize in stainless steel and special alloys, the LRF is designed to handle a wider range of steel grades with higher operational simplicity and reliability.

Feature | LRF Furnace | VOD/VAD Furnace | Basic Oxygen Furnace |

Refining Type | Secondary refining with electric arc | Vacuum refining | Primary refining |

Heating Method | Electric arc heating | Induction or arc under vacuum | Exothermic oxidation |

Inclusion Removal | Excellent | Very good | Moderate |

Alloy Flexibility | High | High | Limited |

Applicable Steel Types | All grades including carbon and alloy steels | Special and stainless steels | Carbon steels |

This comparison shows how the LRF furnace provides the perfect balance between flexibility and metallurgical precision. Its secondary refining capability ensures that the molten steel achieves perfect compositional balance before solidification, improving both structural and surface integrity in the final product.

How Advances LRF Steel Making Through Innovation

In the field of LRF steel making, CHNZBTECH, one pf the excellent steel furnace manufacturers, has become a symbol of advanced engineering and reliable performance. Through the integration of real-time temperature monitoring, argon purging systems, and automated alloy feeding, CHNZBTECH's LRF furnace provides operators with unmatched control over the refining process. The company's designs emphasize metallurgical efficiency, energy optimization, and stable thermal performance — all critical factors in ensuring that each batch of steel meets international standards. With a focus on sustainable, efficient, and precise refining technology, CHNZBTECH continues to contribute to the global steel industry by providing LRF systems that combine advanced design with proven durability. These technologies enable steelmakers to achieve cleaner, more consistent, and higher-grade steel, reinforcing the essential role of the LRF furnace in the modern steelmaking process.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa