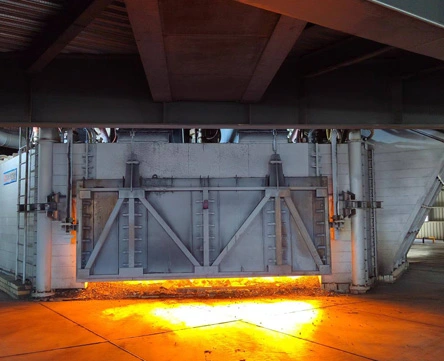

CHNZBTECH announced the successful commissioning and first steel tap from its newly delivered 140-ton Ladle Refining Furnace (LRF), engineered exclusively for a major Chinese steel producer. The furnace achieved operational status immediately after installation, marking a significant milestone in the project.

The precision-engineered system entered production following a streamlined commissioning process, meeting all technical specifications during its inaugural operational cycle. This single-phase success underscores CHNZBTECH’s capability in delivering complex metallurgical systems tailored to specialized industrial requirements.

"Our team prioritized design integration with the client’s existing workflow," stated a CHNZBTECH Project Engineer. "The seamless startup demonstrates how custom solutions can optimize production continuity for large-scale operators."

The furnace enhances the steelmaker’s capacity for producing specialized steel grades, with its rapid commissioning minimizing facility downtime. CHNZBTECH technicians remain on-site to monitor initial production cycles and ensure performance stability. This project reinforces CHNZBTECH’s position as a provider of mission-critical metallurgical equipment for China’s leading industrial enterprises. By integrating smart automation, LRF in steel making reduces material waste and improves production efficiency.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa