Understanding the DC Electric Arc Furnace in Steelmaking

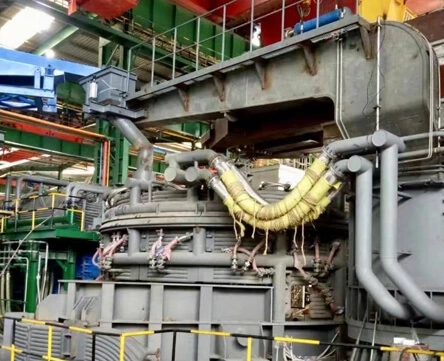

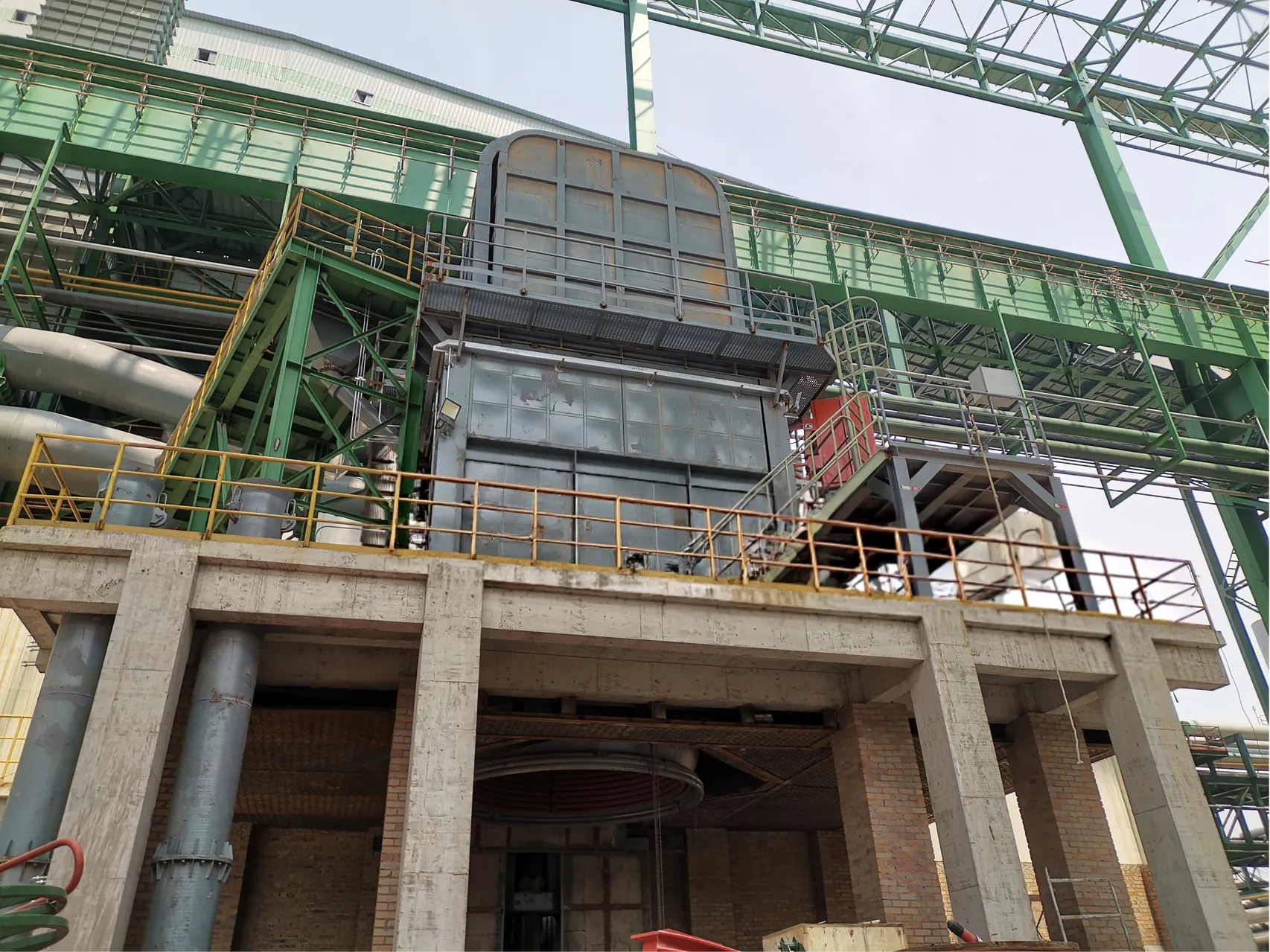

The DC electric arc furnace has become one of the most advanced and efficient technologies in the modern steelmaking process. Unlike traditional alternating current furnaces, the DC system uses a direct current to generate an arc between a single graphite electrode and the molten bath, producing intense heat that melts scrap or raw materials. This process not only improves energy utilization but also enhances temperature control and metallurgical precision. CHNZBTECH, a globally recognized leader in furnace engineering, provides cutting-edge DC electric arc furnace systems designed for high productivity and energy efficiency. The technology is essential for producing high-quality steel used in industrial machinery, structural materials, and stainless-steel furniture — including durable and aesthetically refined dining tables that require superior metallurgical consistency and surface finish.

How the DC Electric Arc Furnace Improves Efficiency and Quality

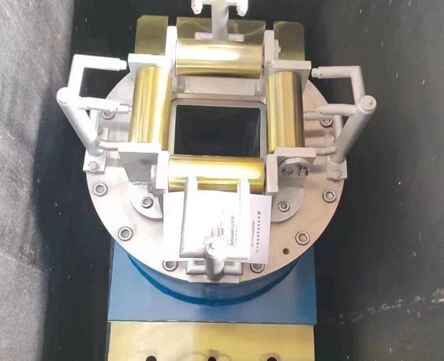

The working principle of the DC electric arc furnace lies in its ability to establish a stable and concentrated heat source through a single graphite electrode, with the return current passing through the molten metal and the bottom electrode. This configuration minimizes power fluctuations and energy loss, resulting in higher thermal efficiency and faster melting times. The steady arc also reduces electrode consumption and noise, creating a cleaner working environment. CHNZBTECH has refined this process through advanced simulation and automation systems, allowing operators to maintain consistent furnace conditions and optimize metallurgical reactions. The outcome is steel with precise chemical composition and superior purity, ideal for applications where surface appearance and corrosion resistance are critical — such as polished stainless steel tables used in kitchens, restaurants, and interior spaces.

DC Electric Arc Furnace vs. AC Electric Arc Furnace: A Comparative View

A high-quality electric arc furnace provides higher throughput, lower operating cost per ton, and a reduced carbon footprint for your steel plant. To understand why the DC electric arc furnace has gained widespread adoption, it's important to compare it with traditional AC designs. CHNZBTECH engineers utilize both systems in their projects, but emphasize that DC furnaces offer clear technical advantages for specific metallurgical goals.

Feature | DC Electric Arc Furnace | AC Electric Arc Furnace |

Power Supply | Direct current | Alternating current |

Electrode Configuration | Single top electrode | Three electrodes |

Arc Stability | Highly stable and concentrated | Fluctuates with current change |

Energy Efficiency | Higher due to lower losses | Lower efficiency |

Noise and Vibration | Reduced | Relatively high |

Electrode Wear | Minimal | Higher due to phase change |

Maintenance Frequency | Lower | Higher |

Understanding the types of steel making furnaces helps you choose the right route for cost, quality, and emissions. This comparison highlights how the DC model achieves smoother operation, reduced power demand, and longer equipment lifespan. These advantages contribute to consistent steel quality, which in turn supports industries that rely on flawless metallic finishes, such as those producing stainless dining tables and kitchen installations where both strength and elegance are required.

Why DC Electric Arc Furnace Technology Matters for Modern Steel Products

In the production of refined steel used for home furnishings, architecture, and manufacturing, the DC electric arc furnace offers unmatched control over temperature and composition. Its stable operation allows for uniform melting and thorough refining, ensuring that impurities are effectively removed while alloy elements are preserved. This balance results in steel that is dense, resilient, and capable of maintaining a polished surface finish over time. CHNZBTECH's implementation of DC technology ensures that the entire process is both environmentally efficient and metallurgically precise. For stainless steel dining tables — where visual appeal, durability, and hygiene are key — the uniform structure achieved through DC melting contributes to smooth surfaces, resistance to corrosion, and long-term performance. Every finished product reflects the precision achieved during the steelmaking stage, making the DC electric arc furnace a cornerstone of modern material excellence.

CHNZBTECH's Contribution to Advanced Furnace Solutions

In the production of refined steel used for home furnishings, architecture, and manufacturing, the DC electric arc furnace offers unmatched control over temperature and composition. Its stable operation allows for uniform melting and thorough refining, ensuring that impurities are effectively removed while alloy elements are preserved. This balance results in steel that is dense, resilient, and capable of maintaining a polished surface finish over time. CHNZBTECH's implementation of DC technology ensures that the entire process is both environmentally efficient and metallurgically precise. For stainless steel dining tables — where visual appeal, durability, and hygiene are key — the uniform structure achieved through DC melting contributes to smooth surfaces, resistance to corrosion, and long-term performance. Every finished product reflects the precision achieved during the steelmaking stage, making the DC electric arc furnace a cornerstone of modern material excellence.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa