Understanding the AOD Furnace and Its Importance in Steel Refining

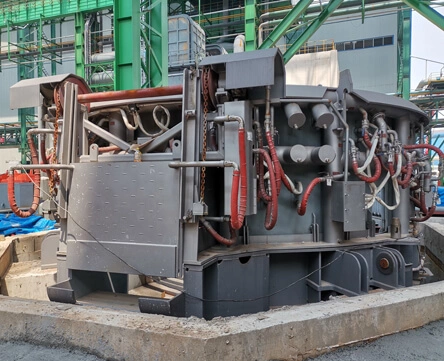

In modern stainless steel production, the AOD furnace stands as one of the most crucial technologies in achieving precise chemical composition control and high-quality steel output. This refining unit operates as an advanced metallurgical converter, typically used after melting in an electric arc furnace (EAF). CHNZBTECH, a global leader in metallurgical engineering, designs and supplies high-performance AOD furnaces that integrate precision, efficiency, and automation. By injecting a mixture of oxygen, argon, and nitrogen into molten metal, the AOD process refines the steel by removing carbon and other impurities without significant loss of valuable alloying elements like chromium or nickel. The process ensures a cleaner, more stable melt — a key step in producing superior stainless steel for critical applications such as kitchenware, industrial machinery, and architectural materials.

How the AOD Furnace Works in the Refining Process

The AOD furnace operates by injecting gas mixtures through submerged tuyeres in the converter's bottom or sidewall. The controlled introduction of oxygen promotes the oxidation of carbon, forming carbon monoxide gas that escapes through the molten surface. To minimize chromium oxidation — which is undesirable — argon or nitrogen is mixed with oxygen, diluting its concentration. This delicate balance between oxidation and reduction phases allows precise control over carbon content while retaining essential alloy elements. CHNZBTECH's AOD furnaces employ advanced flow regulation systems and automated control software, enabling operators to manage every stage of decarburization and desulfurization efficiently. The result is consistent molten steel with exceptional purity and composition accuracy. For industries where steel strength, corrosion resistance, and surface finish matter, such as kitchen equipment manufacturing or food-grade tableware, the AOD furnace remains an indispensable tool.

AOD Furnace vs. Conventional Refining Units

When comparing the AOD furnace to other secondary refining equipment, the differences become evident in performance, flexibility, and efficiency. CHNZBTECH's expertise in engineering furnaces allows for an optimized design that surpasses traditional systems like VOD (Vacuum Oxygen Decarburization) in specific scenarios.

Feature | AOD Furnace | Conventional Refining Unit |

Gas Atmosphere | Argon-Oxygen mixture | Pure Oxygen or Vacuum |

Carbon Removal Efficiency | High, with minimal alloy loss | Moderate, higher alloy oxidation |

Application | Ideal for stainless and alloy steels | Common for plain carbon steels |

Temperature Control | Stable with automated systems | Requires manual adjustments |

Alloy Recovery Rate | Excellent | Average |

This comparison shows why many stainless steel producers prefer AOD furnaces for refining processes. Their ability to maintain chemical integrity while achieving rapid decarburization gives them a distinct advantage, particularly when alloy preservation is critical for maintaining product performance and visual appeal.

Why AOD Furnaces Are Essential for Stainless Steel Products

The production of stainless steel components, including restaurant tables, kitchen sinks, utensils, and decorative surfaces, relies heavily on the purity and consistency of the molten steel. The AOD furnace ensures these characteristics by enabling refined control of sulfur, carbon, and oxygen levels. Through advanced gas mixing and temperature control, CHNZBTECH's AOD furnace allows for stable compositions that prevent surface blemishes, improve corrosion resistance, and enhance mechanical strength. In industries that demand both durability and aesthetics — such as hospitality, dining, and home furnishing — the materials refined by the AOD process contribute directly to the final product's quality. Stainless steel tables, for instance, must combine strength with visual appeal, a balance that can only be achieved when the base metal is refined under optimal AOD furnace conditions.

CHNZBTECH's Innovation in AOD Furnace Technology

CHNZBTECH's AOD furnace solutions reflect a strong commitment to metallurgical innovation and engineering precision. The company's technology emphasizes uniform gas flow, efficient thermal management, and high automation levels. Every furnace is designed using advanced 3D modeling simulation to ensure reliability and long service life. These systems are applied in large-scale steel plants across Egypt, Türkiye, Algeria, Iran, and Russia, supporting continuous steel production for diverse industries. By integrating modern automation and robust refractory design, CHNZBTECH, as a leading player among steel furnace manufacturers, enables smoother operations and stable refining performance. For steel manufacturers focusing on quality enhancement and consistent composition control, the AOD furnace represents not just equipment but a strategic advantage in global steelmaking.

Zhao Lianggang

Mr. Zhao, a graduate of Shaanxi Normal University, is an expert in metallurgical and steel equipment. With a robust knowledge of EAF, LF, VD/VOD, CCM, and related processes, he possesses a deep understanding of industry trends and customer needs. As a co-founder of CHNZBTECH, he leads the company's international strategy, expanding operations into over 20 countries across the Middle East, Southeast Asia, Africa, and South America. By merging his metallurgical expertise with global market insights, he has driven significant overseas growth and solidified the company's competitive position in the international metallurgical equipment industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa