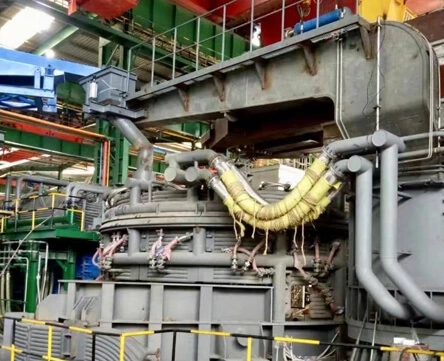

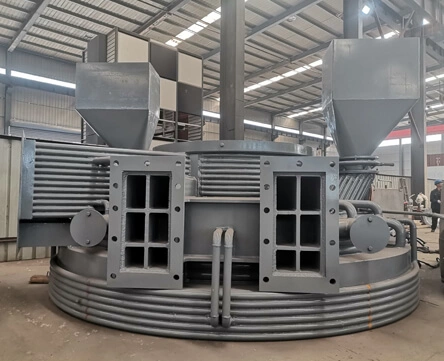

This project represents a major milestone in the development of China’s ferrosilicon industry. As the largest DC ferrosilicon furnace in China, the 45,000 kVA DC furnace EPC project demonstrates a breakthrough in furnace scale, process stability, and energy efficiency, setting a new benchmark for high-end ferroalloy production.

Key Specifications

Project Type: EPC – Engineering, Procurement & Construction

Furnace Type: DC Submerged Arc Furnace

Rated Transformer Capacity: 45,000 kVA

Product: Ferrosilicon

Power Supply System: High-voltage DC rectifier system with optimized harmonic control

Cooling System: Combined water-cooled and forced cooling design for key furnace components

Automation Level: High-level automation with real-time monitoring of electrical, thermal, and process parameters

Environmental Design: Low-emission operation with improved energy utilization efficiency

Technological Innovation

The project adopts an advanced direct current (DC) furnace technology, integrating innovative electrical design, optimized furnace structure, and intelligent process control. Compared with conventional AC furnaces, this large-capacity DC solution reflects a significant leap in China’s independent engineering and manufacturing capabilities for ultra-large ferroalloy furnaces.

Advantages of DC Furnace Technology

DC furnace technology offers clear and proven advantages, especially for large-scale ferrosilicon production:

Improved Process Stability: A single-electrode DC arc provides a more stable melting zone, minimizing arc fluctuation and improving furnace controllability.

Lower Electrode Consumption: Optimized arc characteristics reduce electrode wear, lowering operating costs and improving furnace availability.

Enhanced Metal Recovery: Uniform thermal conditions improve reaction efficiency, leading to higher silicon recovery rates.

Reduced Environmental Impact: Lower energy loss and improved smelting efficiency contribute to reduced emissions and a smaller carbon footprint.

Industry Impact

As China’s largest DC ferrosilicon furnace project, this EPC undertaking not only demonstrates technical leadership but also sets a new reference for high-capacity, low-energy, and environmentally friendly ferroalloy production. The successful implementation of this project marks an important step toward the modernization, scaling-up, and green transformation of China’s ferroalloy industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa