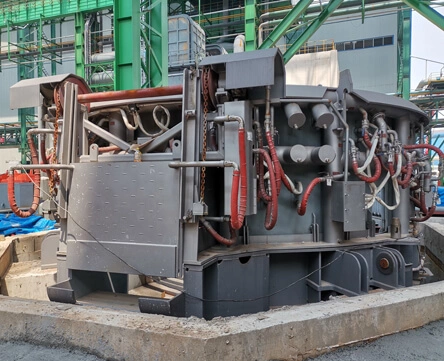

CHNZBTECH has recently achieved another milestone by successfully participating in the R&D, design, installation, and commissioning of a state-of-the-art Electric Arc Furnace (EAF) project. The 120-ton Consteel® EAF, with a furnace shell diameter of 6,500 mm and powered by a 100 MVA transformer, has been put into smooth operation.

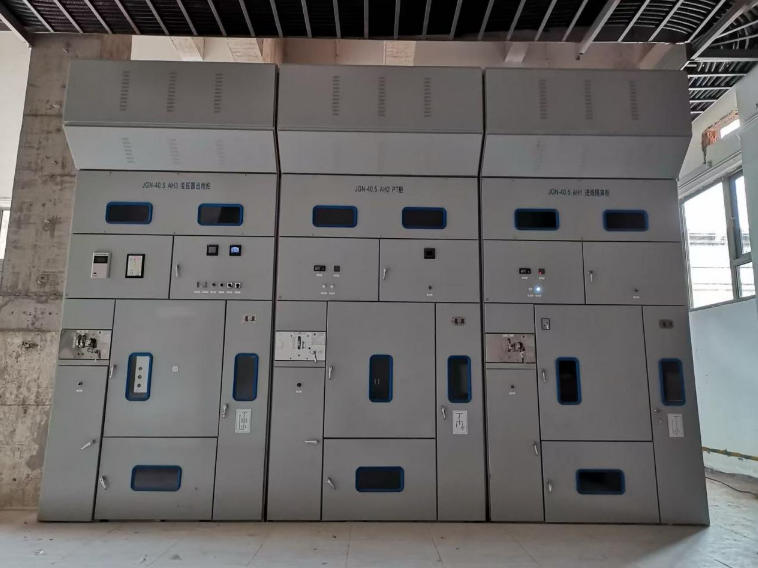

The furnace demonstrates excellent performance, achieving a tapping time of just 45 minutes with a power consumption of 380 kWh per ton of steel. Equipped with the most advanced electrical control systems, the high-quality electric arc furnace is seamlessly integrated with a refining furnace (LF) and a slab continuous caster (CCM), ensuring efficient downstream operations.

With the first slabs successfully cast, this project marks a significant step in delivering high-quality steel production and reinforces CHNZBTECH’s expertise in turnkey EAF solutions. The successful commissioning once again proves the company’s strength in providing reliable technology, efficient design, and high-level project execution for the global steelmaking industry.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa