Background

CHNZBTECH - XI'AN HONGXIN possesses extensive experience in Submerged Arc Furnace (SAF) technology, having successfully executed over 500 SAF projects globally, with specialized proficiency in silicon metal production. This proven track record led GFA to select CHNZBTECH as the EPC turnkey contractor for their 2×33MVA silicon metal furnace project in Oman, relying on our technical expertise to ensure project success.

Project Execution

Throughout the project, CHNZBTECH has maintained proactive and transparent communication with GFA. We regularly organize virtual meetings to address critical challenges, align on technical solutions, and ensure seamless progress. To streamline document management, CHNZBTECH implements a structured transmittal numbering system for all shared files. This practice, though not a core contractual requirement, significantly enhances communication efficiency and precision — a level of professionalism many leading international SAF suppliers have yet to adopt. We believe industry-wide adoption of standardized design, construction, and communication protocols is essential to delivering superior client service.

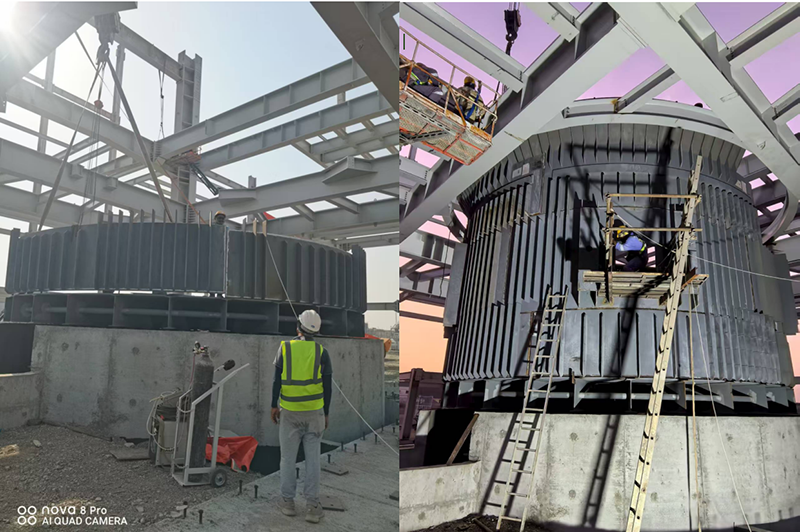

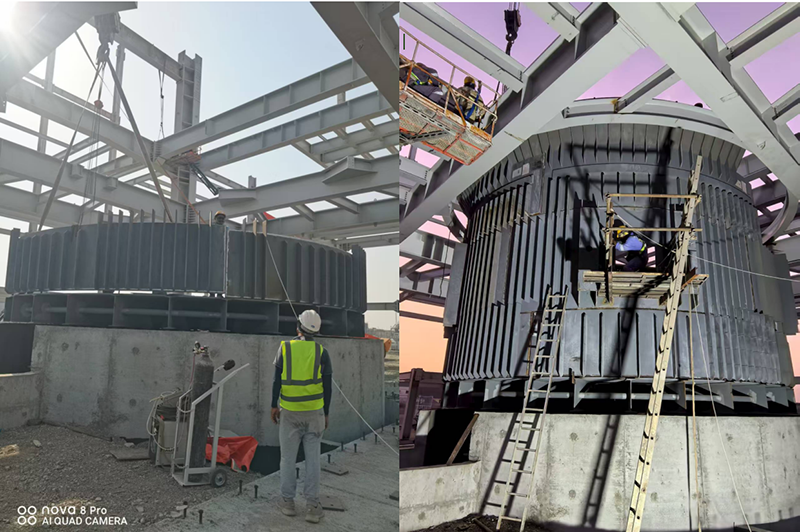

On-site Technical Support & Expertise

To ensure smooth installation and commissioning, CHNZBTECH has proactively dispatched two highly experienced engineers, each with over 15 years of expertise, to the Oman site. They are currently providing expert guidance on the installation of critical components, including the rotating mechanism and steel structures. In the near future, CHNZBTECH plans to deploy a professional team of at least 20 specialized engineers to offer comprehensive on-site supervision and technical assistance throughout the installation phase. This commitment underscores our dedication to ensuring the highest standards of quality and execution.

Innovation & Quality Assurance

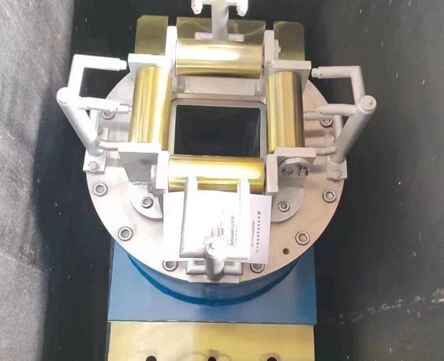

During GFA’s recent factory inspection for the second delivery of equipment, several innovative designs were highlighted, including:

A dedicated lower electrode clamp for large-scale SAFs, ensuring secure, reliable operation and extended lifetime.

An enhanced protective sleeve design for improved cooling efficiency and longevity.

A double-nut connection mechanism for copper tubes in the busbar system, boosting electrical stability and safety.

Conclusion

CHNZBTECH, one of the leading submerged arc furnace suppliers in the market, is committed to integrating advanced engineering solutions and rigorous quality controls into every project phase. Our goal is to ensure clients receive reliable, high-performance equipment and unparalleled service, ultimately guaranteeing satisfaction and trust.

With decades of SAF expertise and a client-centric approach, CHNZBTECH strives to set new benchmarks in the industry. We are dedicated to exceeding expectations in the GFA Oman project, delivering not just a facility, but a long-term partnership built on innovation, quality, and trust.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa