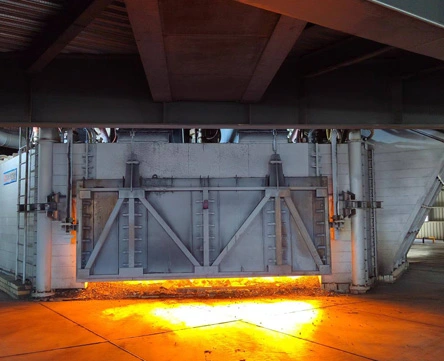

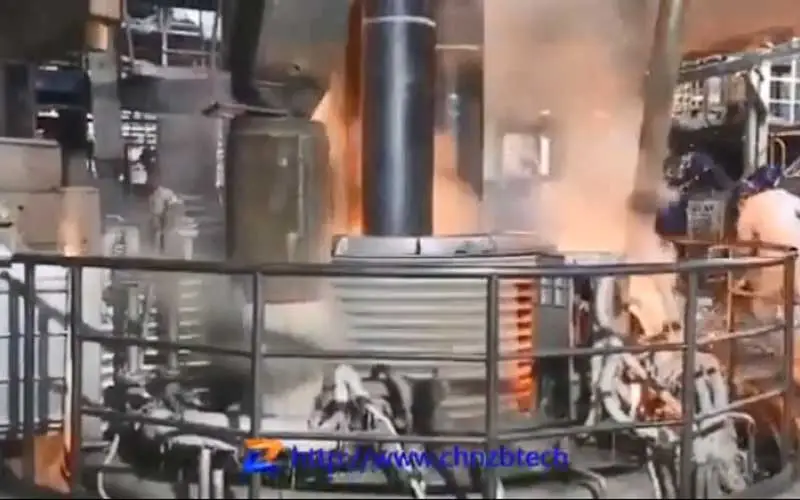

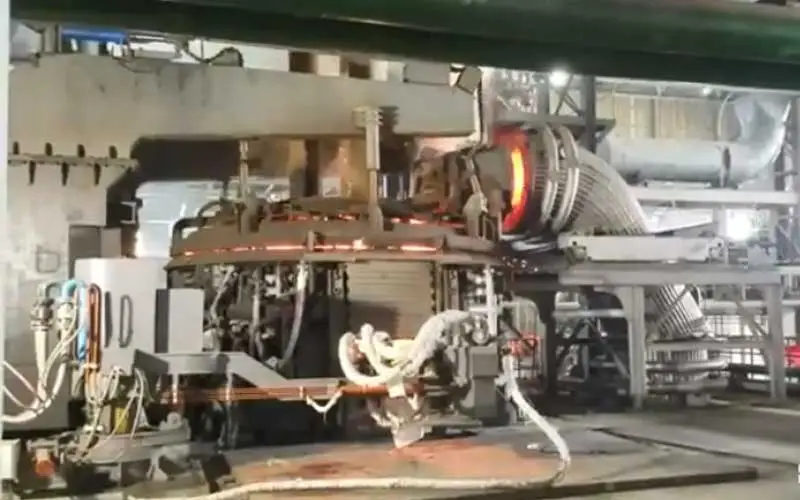

Eccentric Bottom Tapping (EBT) is a key technique incorporated in CHNZBTECH's Electric Arc Furnace (EAF) design, enabling more efficient and controlled tapping of molten steel. This method features a specially designed tapping system with the tapping hole located at an eccentric position at the bottom of the furnace, enhancing the flow and control of molten metal during tapping. By leveraging the expertise of an electric arc furnace manufacturer, this innovative approach enhances productivity and precision in steelmaking processes.

CHNZBTECH’s EBT Advantage:

Improved Steel Quality: The technique reduces slag inclusion and oxidation, resulting in cleaner steel and enhanced product quality.

Operational Efficiency: Eccentric Bottom Tapping improves the efficiency of the tapping process, reducing downtime and increasing overall productivity.

High Durability and Reliability: The advanced design of CHNZBTECH's EBT systems ensures high durability and reliability under demanding furnace conditions.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa