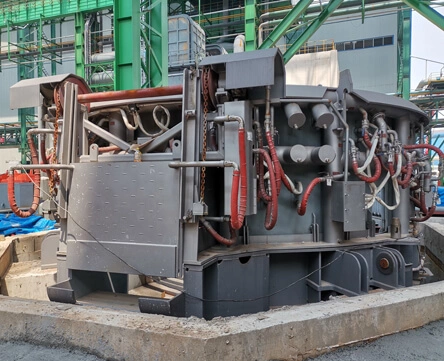

The Ladle Turnover Mechanism is a crucial piece of equipment developed by CHNZBTECH to facilitate the safe and efficient handling of ladles during the steelmaking process. This mechanism is designed to rotate the ladle, allowing for controlled pouring or tipping of molten steel into casting machines or other processing units.

CHNZBTECH's Ladle Turnover Mechanism Advantage:

Reliable Performance: CHNZBTECH’s ladle turnover mechanisms are built for durability and reliability, even in harsh, high-temperature environments, ensuring minimal downtime.

Precision Control: The system provides accurate control of the ladle’s tilt angle, enhancing the precision of pouring and improving product quality.

Customization: The ladle turnover mechanism can be tailored to meet the specific needs of different steel plants, including varying capacities and integration with other plant systems.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa