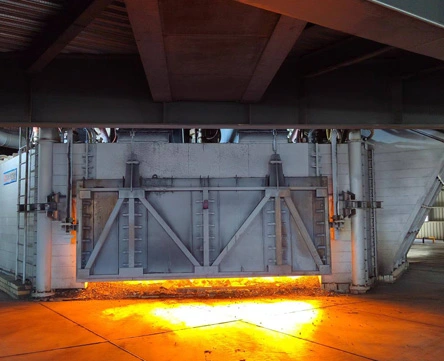

The EAF tapping spout is a vital component in the Electric Arc Furnace (EAF) smelting process, particularly in the equipment produced by CHNZBTECH. It is instrumental in the precise transfer of molten steel from furnaces to ladles or other casting systems during tapping. The design and functionality of this tapping spout reflect the expertise of an electric arc furnace manufacturer, ensuring efficient operations in steel production.

Function:

Molten Steel Transfer: The tapping spout facilitates the flow of molten steel from the EAF, ensuring a smooth and safe discharge.

Temperature and Flow Control: It helps maintain proper temperature control and flow rate during tapping, minimizing the risk of spills or improper casting.

Safety Features: Advanced designs, often including gas sealing and cooling mechanisms, ensure safe operation by preventing heat loss, slag contamination, and oxidation of the steel.

CHNZBTECH's tapping spouts are engineered for durability and reliability, essential for enhancing efficiency and safety during the electric arc furnace tapping process.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa