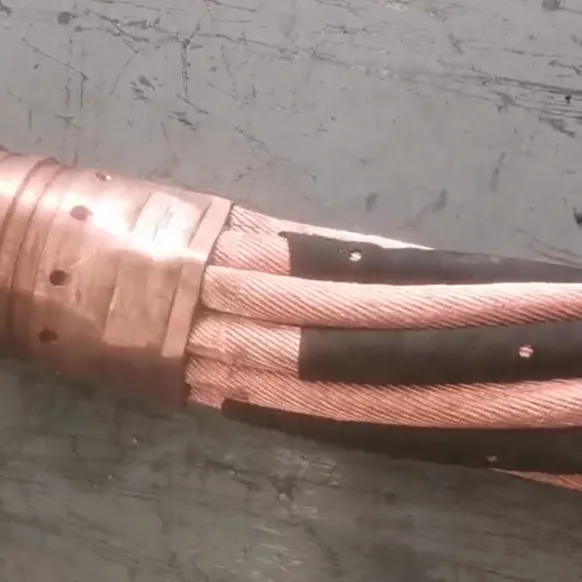

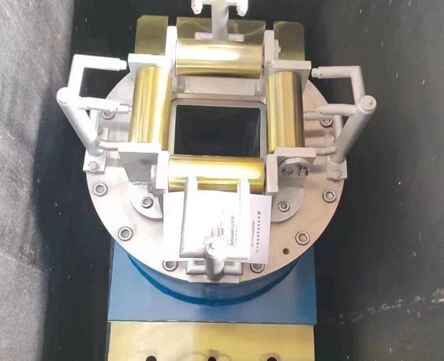

1. Forged Terminal Head Only — We are the only manufacturer in China using 100% forged copper terminal heads, ensuring exceptional conductivity and mechanical strength.

2. High-Purity Copper Material — All cables are made from T2 or TU2 copper, with SGS, BV, or BVI certification available upon request.

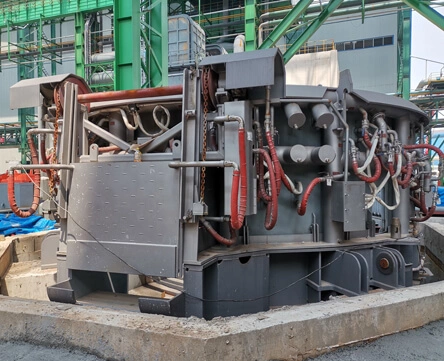

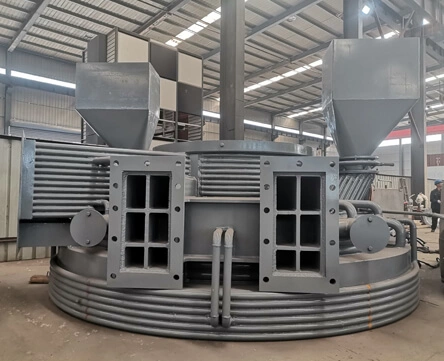

3. Industry Record Holder — The only company in China that has designed and produced water-cooled cables for a 350-ton EAF, with a cross-section of 7500 mm² and a length of 14.5 m.

4. Optional Internal Protection Hose — For enhanced mechanical protection and service life, we provide an additional internal protective hose structure.

5. Full Quality Assurance — Each cable is pressure-tested and electrically tested before shipment to guarantee long-term reliability in harsh steelmaking environments.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa