Lightweight, high stiffness, low impedance, and long service life.

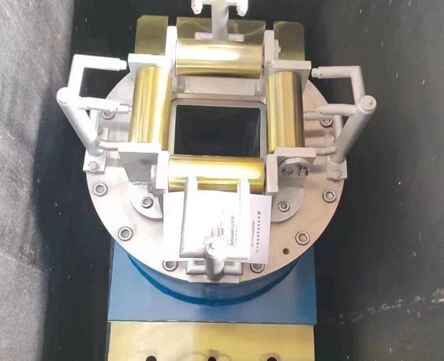

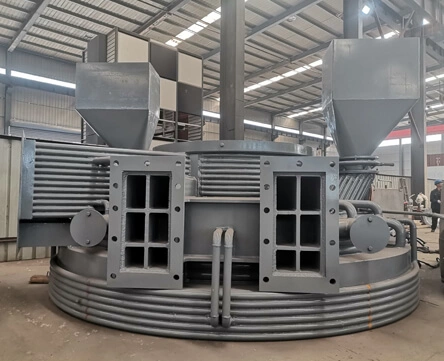

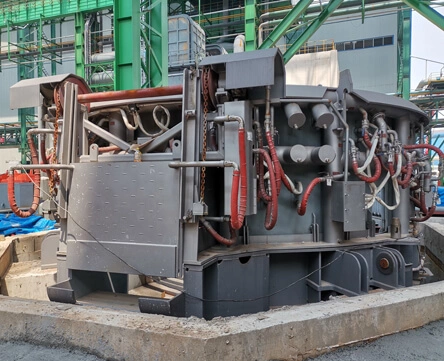

The conductive cross arm is a key component of the electrode lifting system in electric arc furnaces (EAF).

One end of the arm is mounted on the electrode column, while the other end clamps the electrode and enables vertical movement.

The lightweight design minimizes the driving power required for electrode lifting and adjustment, improving operation response and energy efficiency.

The hollow box-section structure combined with a double-layer copper–steel composite plate greatly reduces the skin effect, lowers electrical impedance, and enhances electrothermal efficiency.

As part of the electric furnace, the internal water-cooled channels ensure excellent mechanical strength and thermal stability, maintaining precise electrode positioning and stable arc operation with minimal vibration.

Compared with traditional steel-tube cross arms, this design achieves lighter weight, lower inertia, and longer service life, allowing for frequent and accurate electrode movements.

back homepage

back homepage

EN

EN

fr

fr  ar

ar  fa

fa